OUR RANGE OF FLANGES

Our Range of Flanges

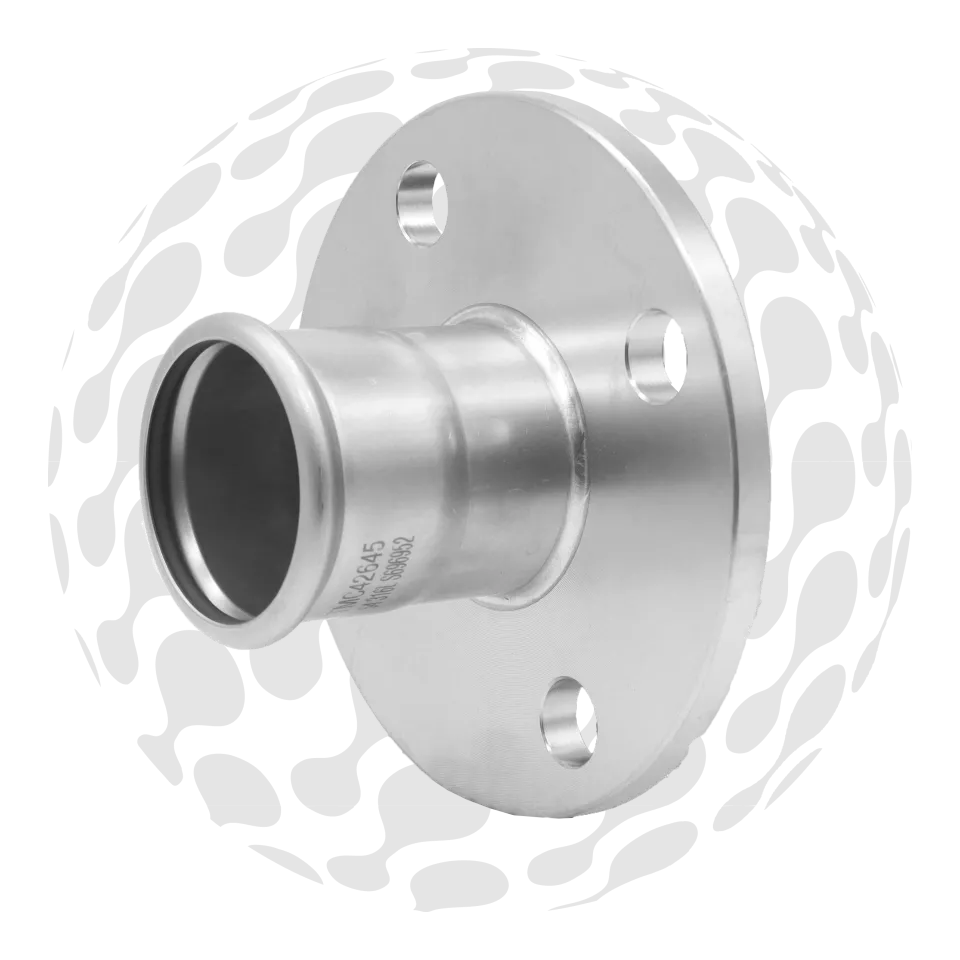

The Metal Company’s range of flanges includes the Tube Flanges, Pipe flanges, BSP threaded flanges, Backup Flanges, and blind flanges.

Flanges are available in various sizes and standards to suit imperial tube, schedule pipe and spiral welded tube. Typical industry applications include irrigation, pumping, petrochemical, geothermal, marine and food & beverage process lines. The Metal Company stock flanges in both Full Thickness & Lightweight thickness to suit your application.

Flanges are used to connect pipes, valves, pumps and other equipment to form a piping system. Flanges also provide easy access for cleaning, inspection or modification.

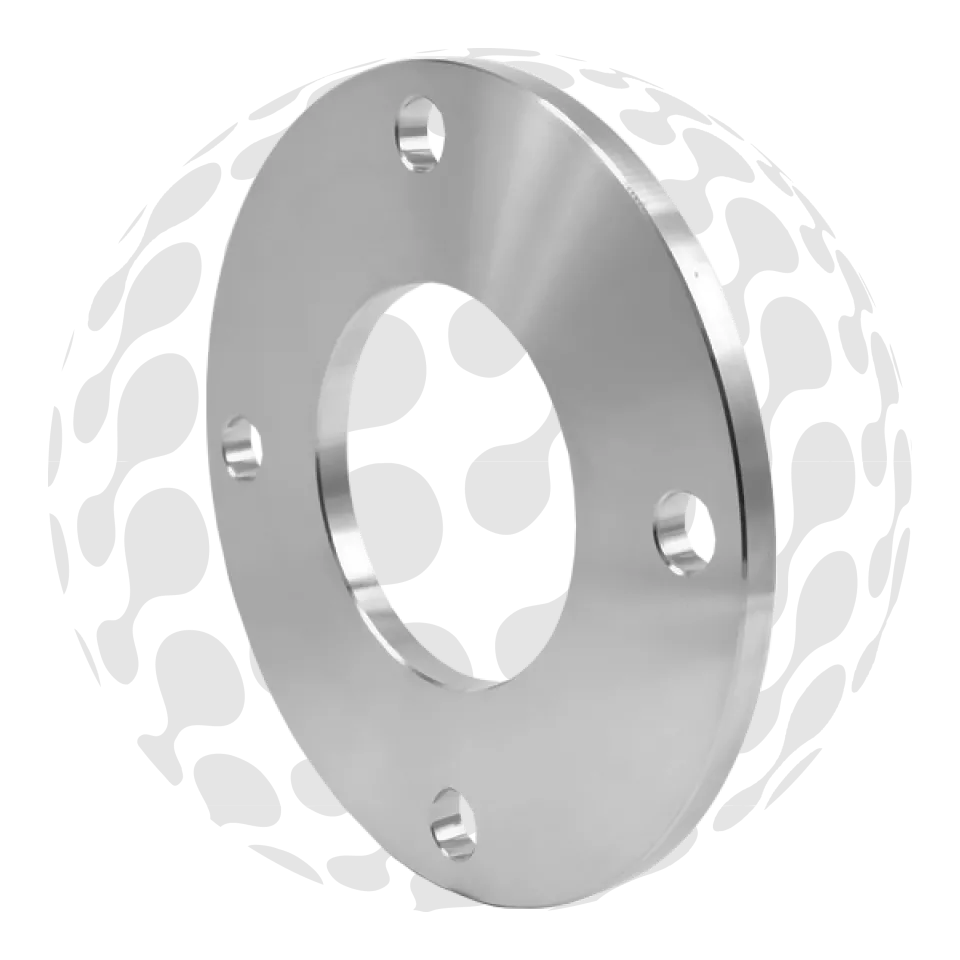

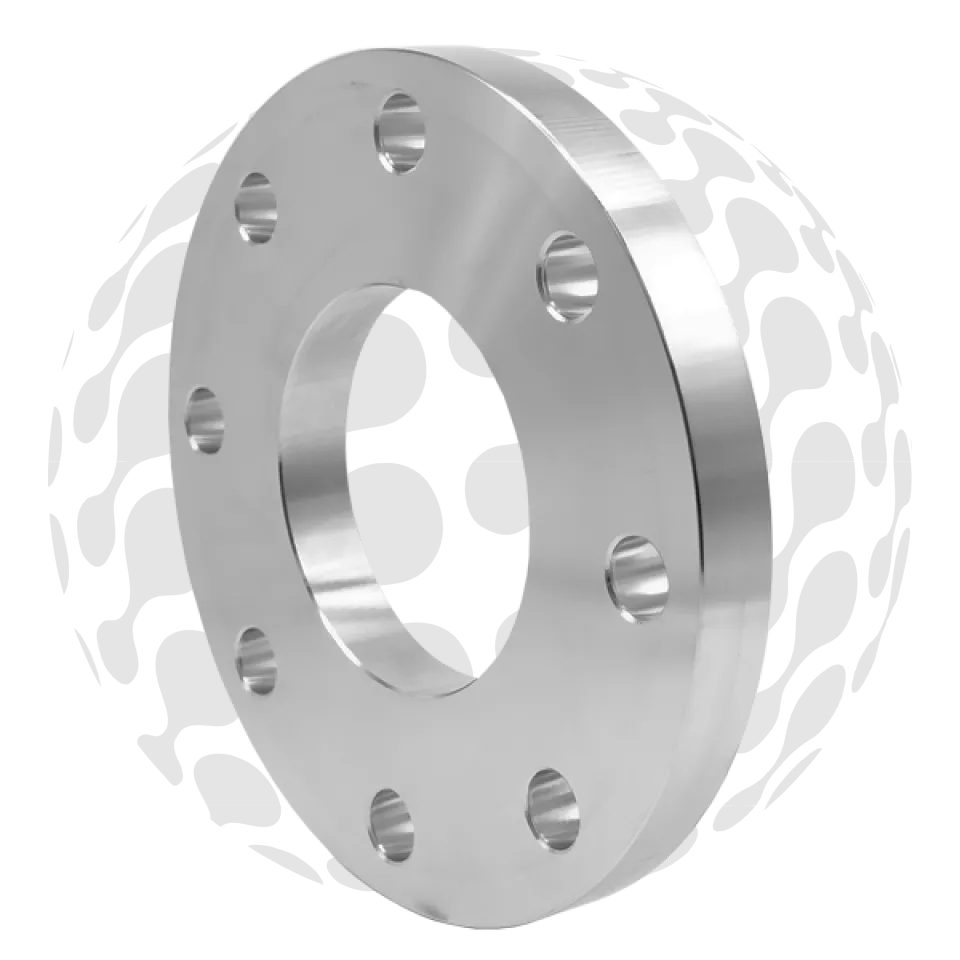

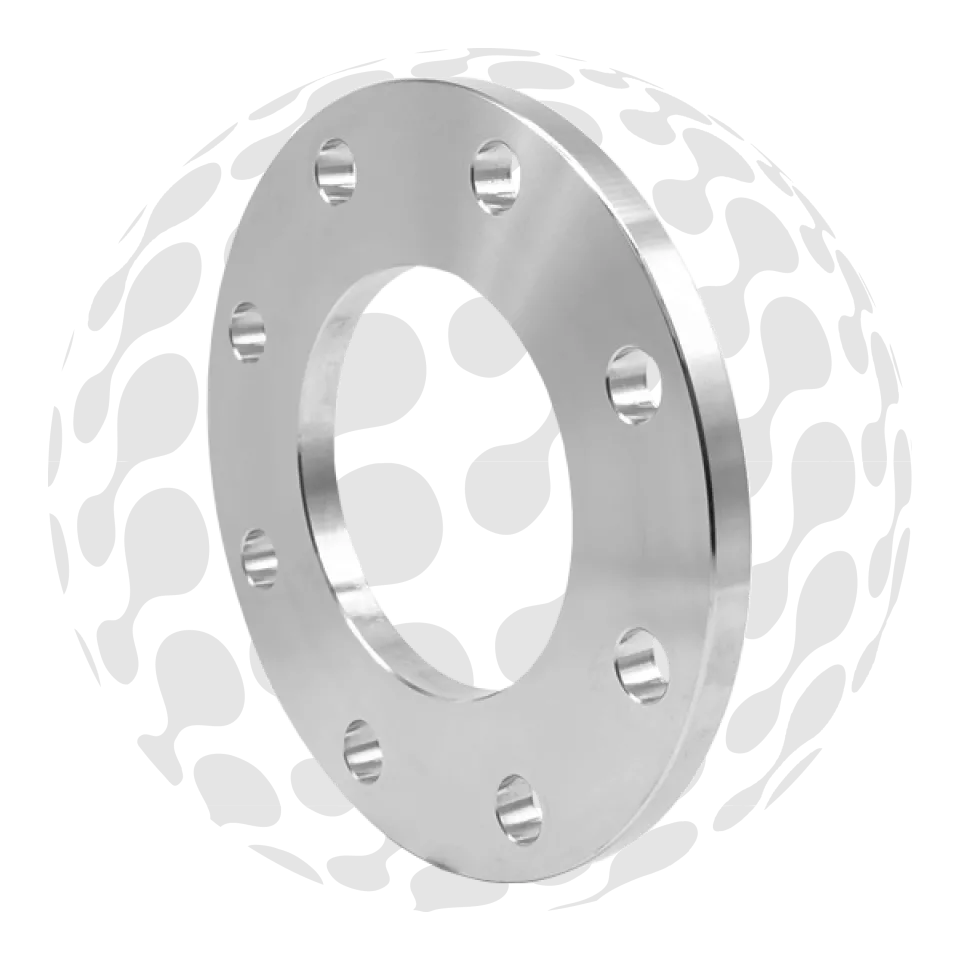

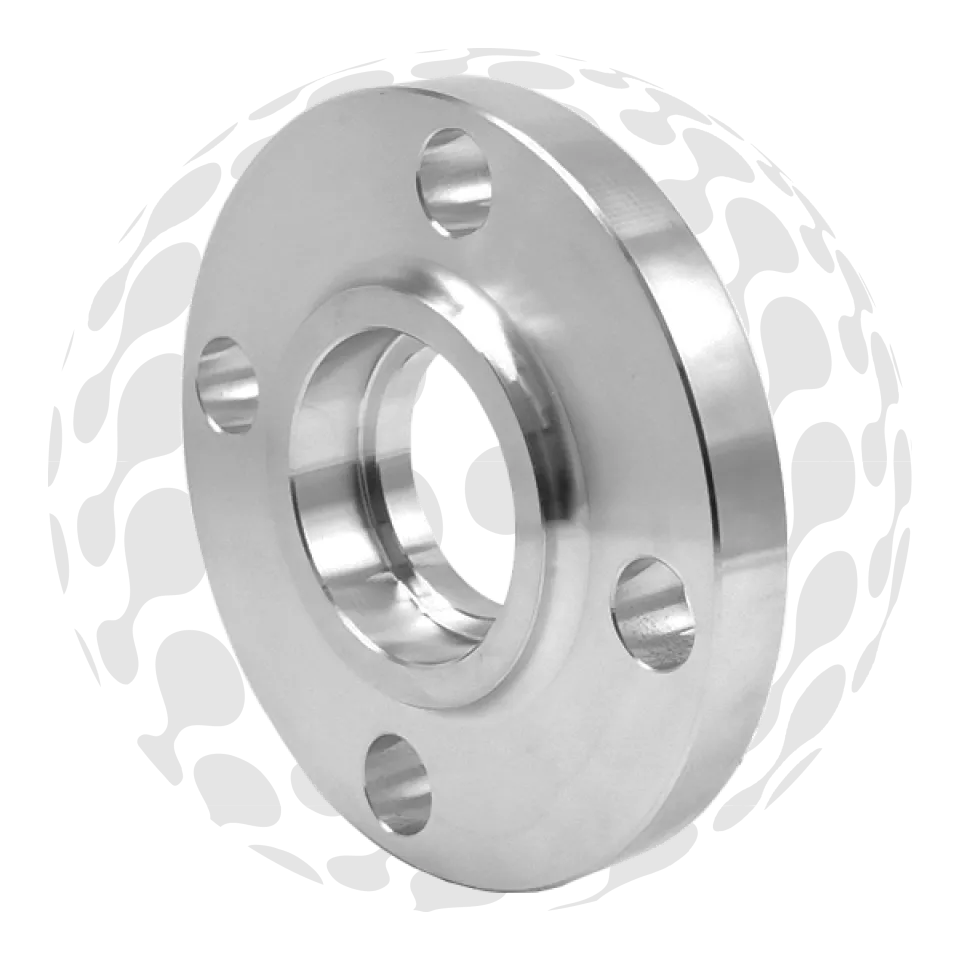

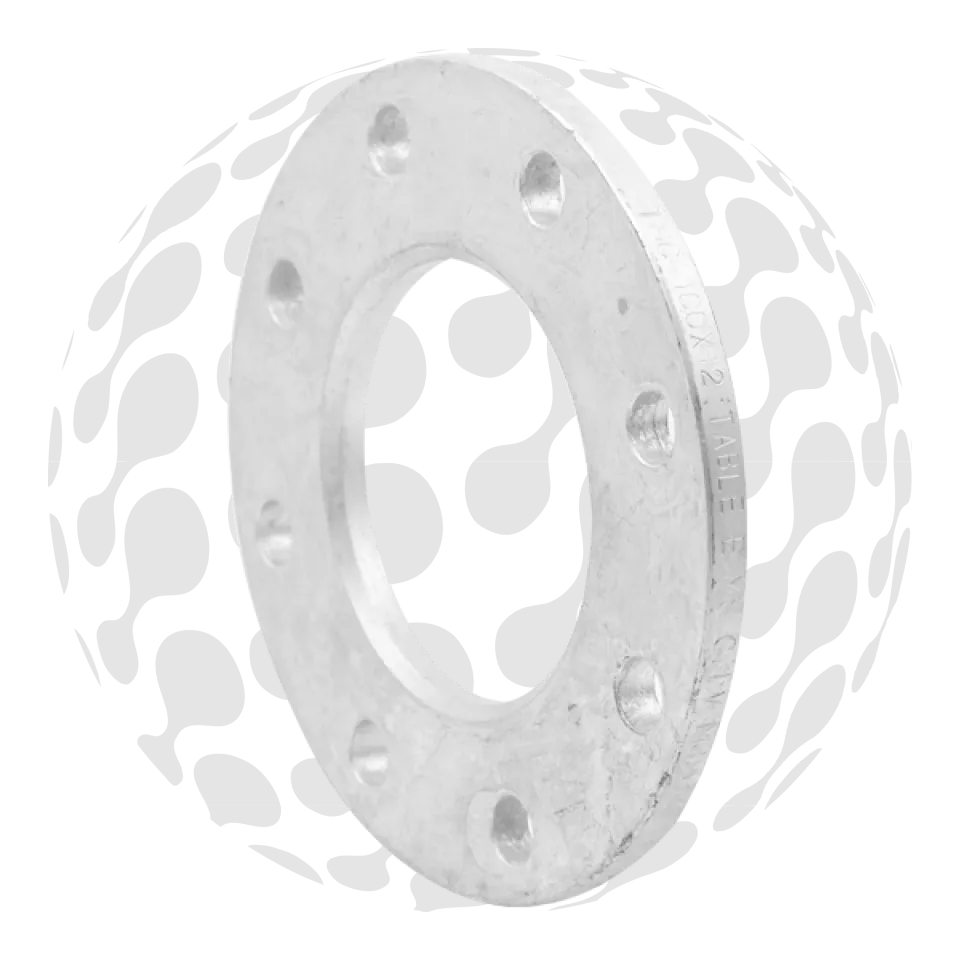

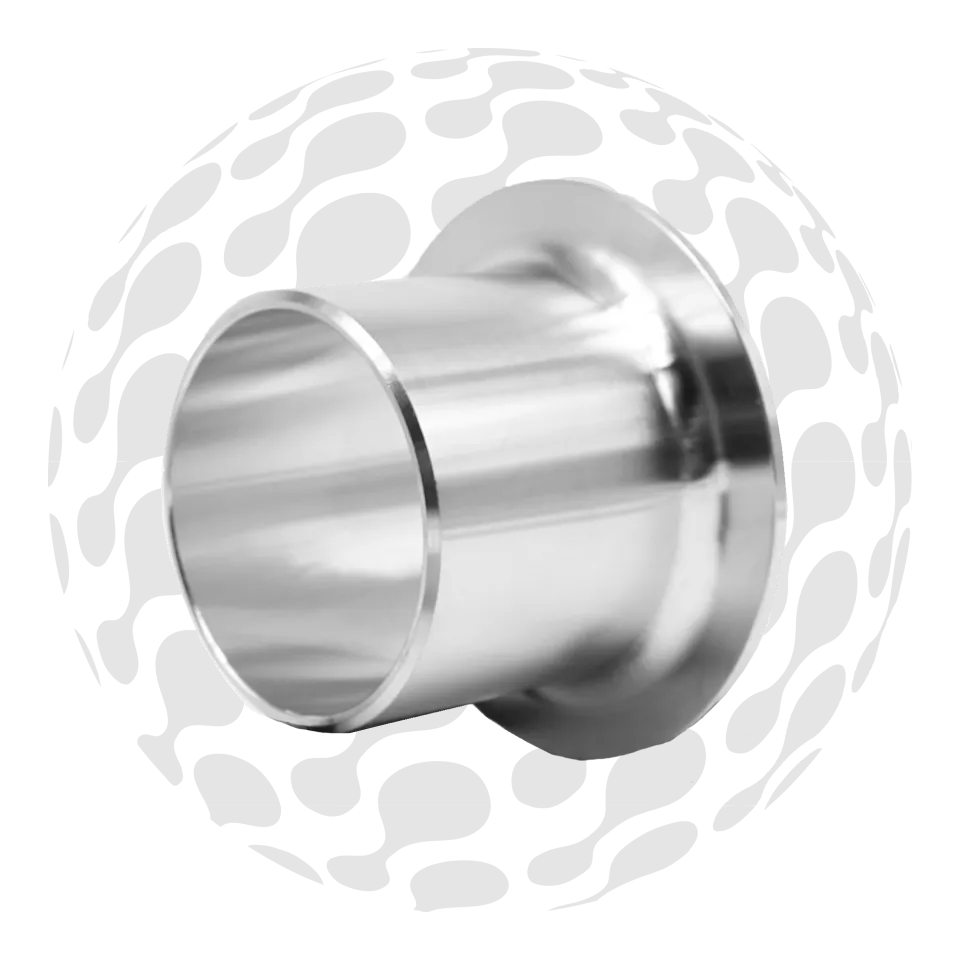

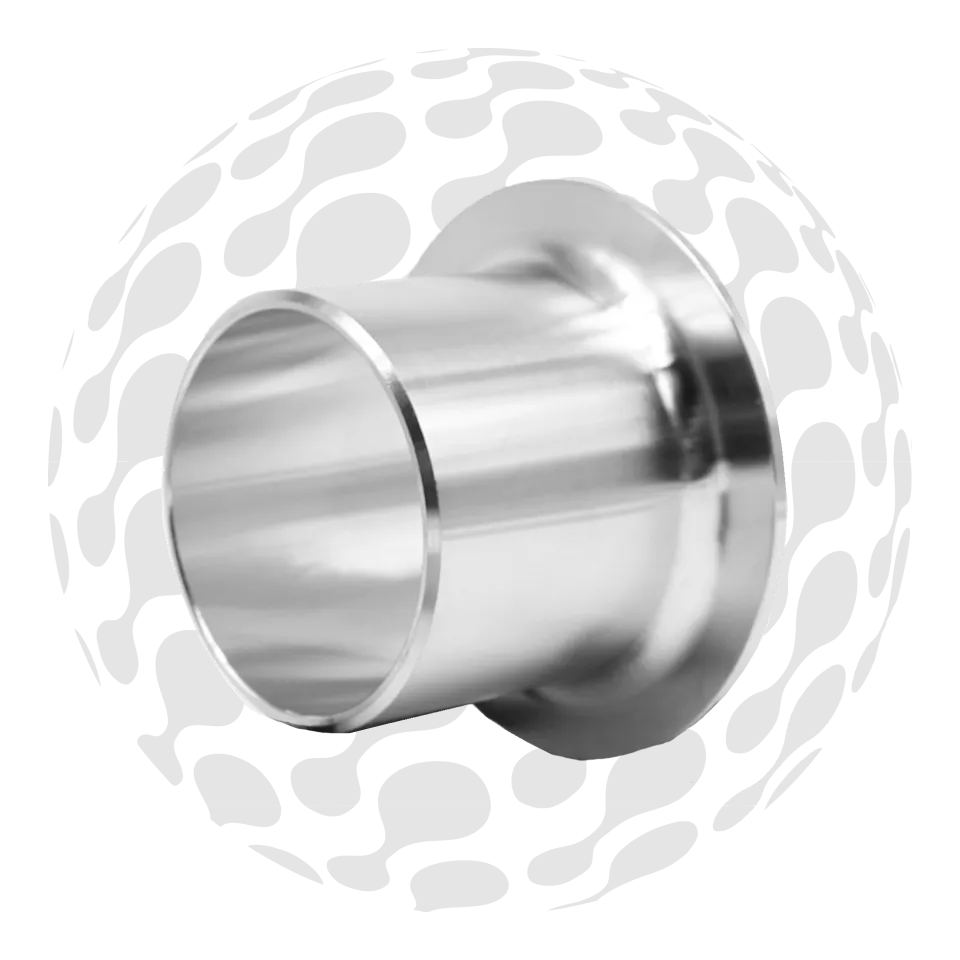

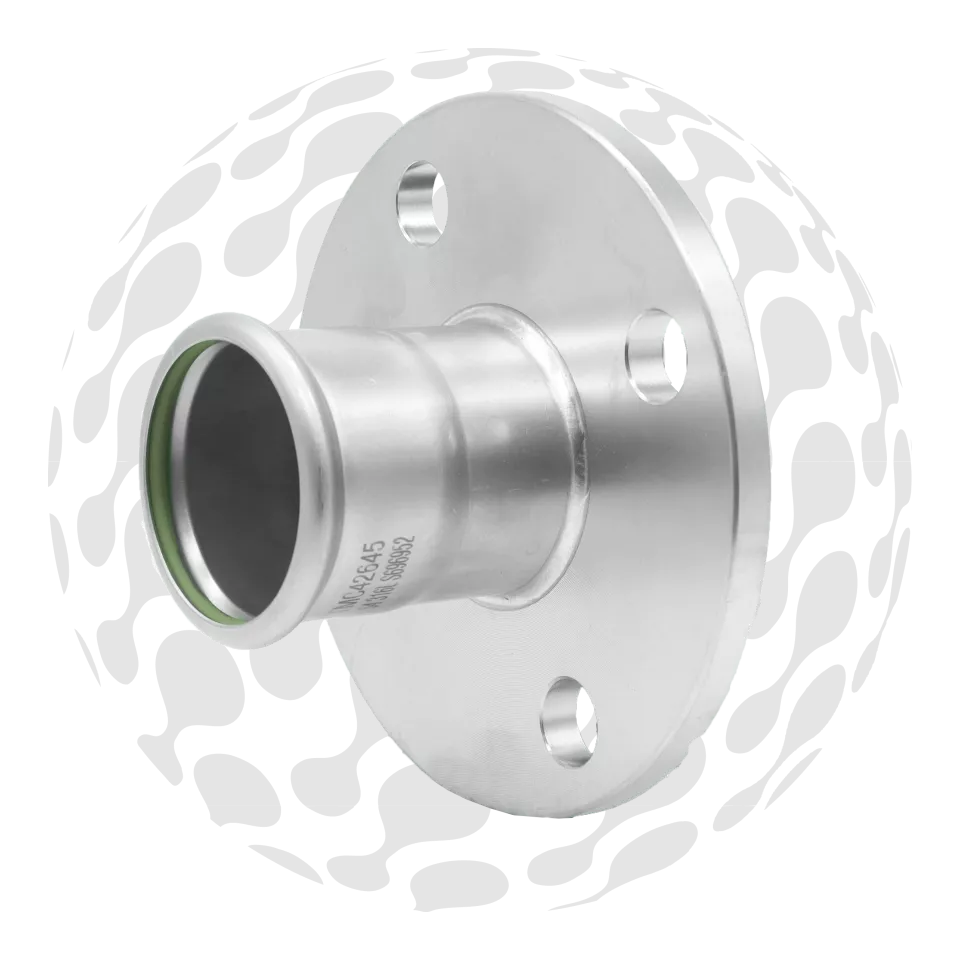

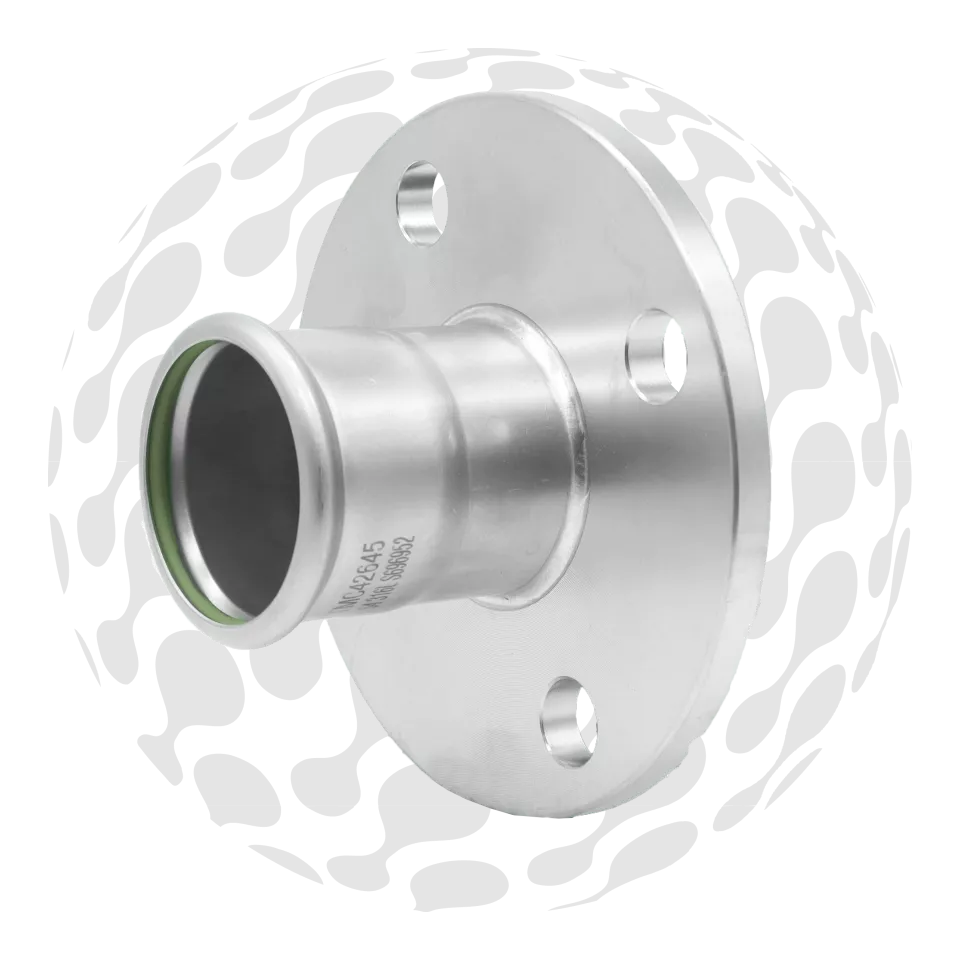

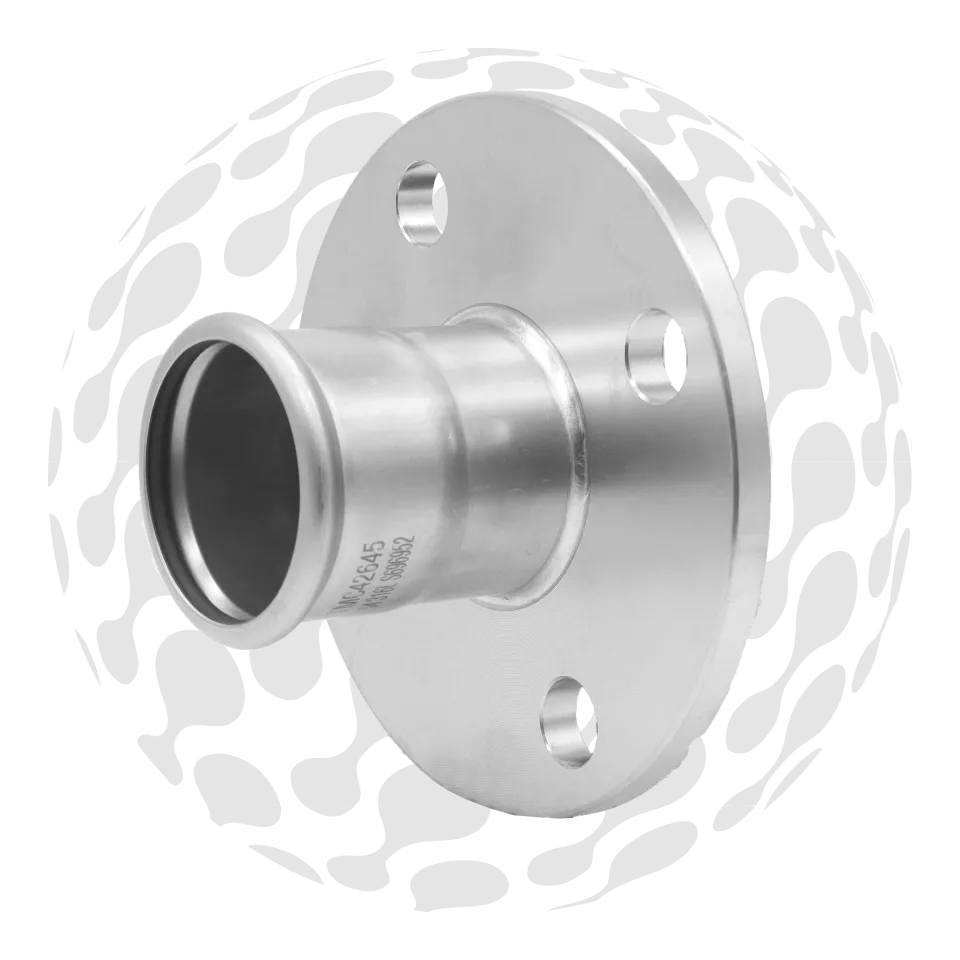

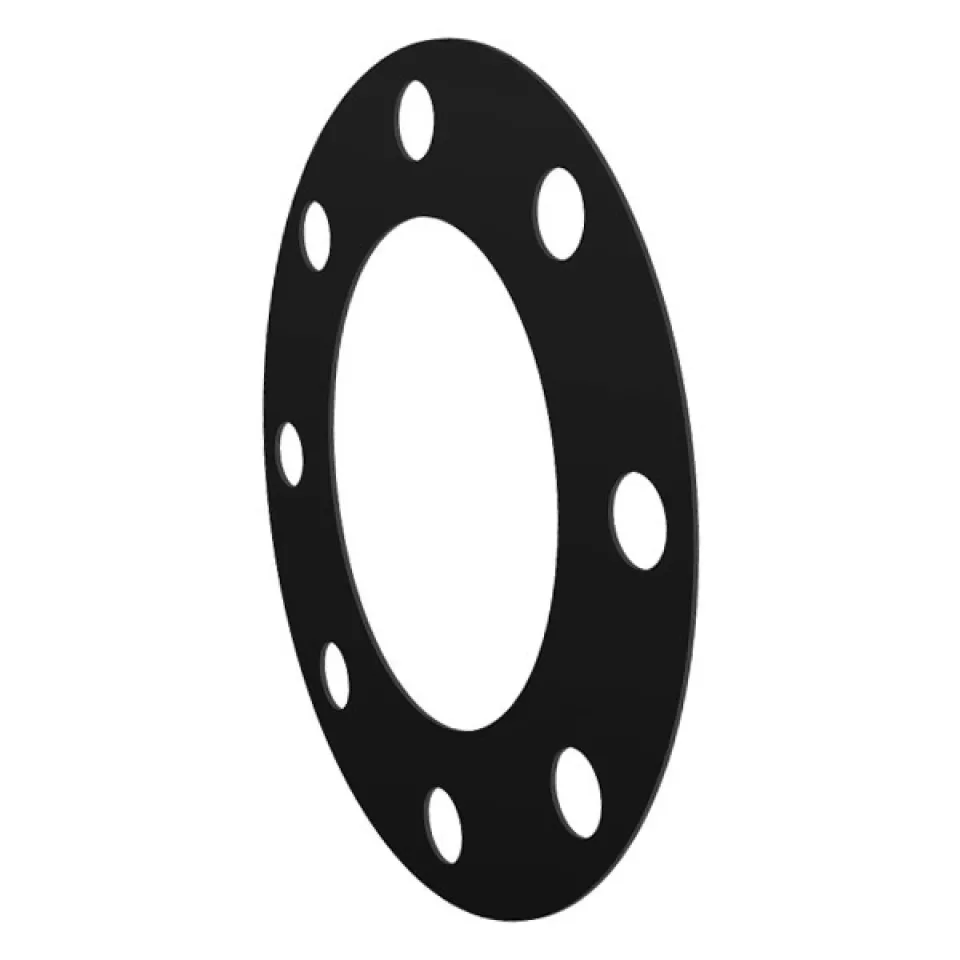

Flat faced slip on flanges are smooth on both sides of the flange. It slips over either tube or pipe and then is welded into place. It is available for both tube and pipe to suit standards for Table E, Table D, PN10-16, ANSI150, PN16 and AS4087 for pipe.

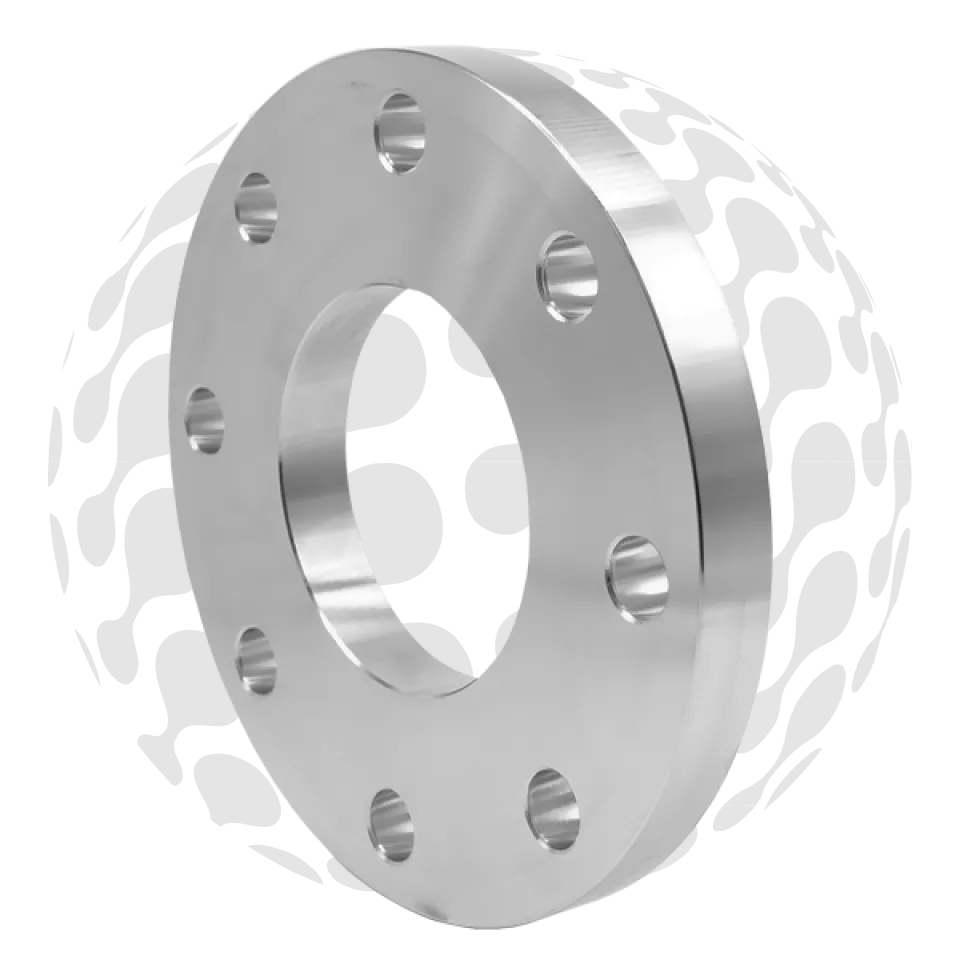

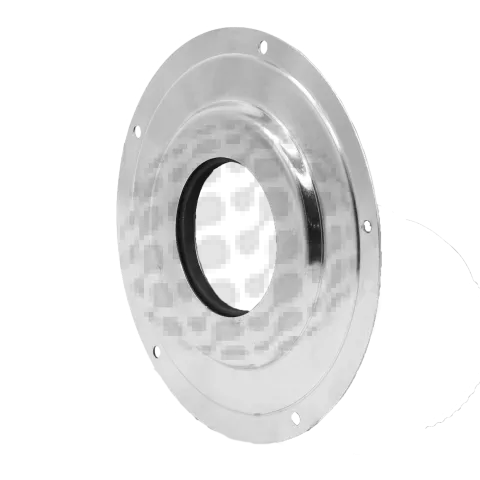

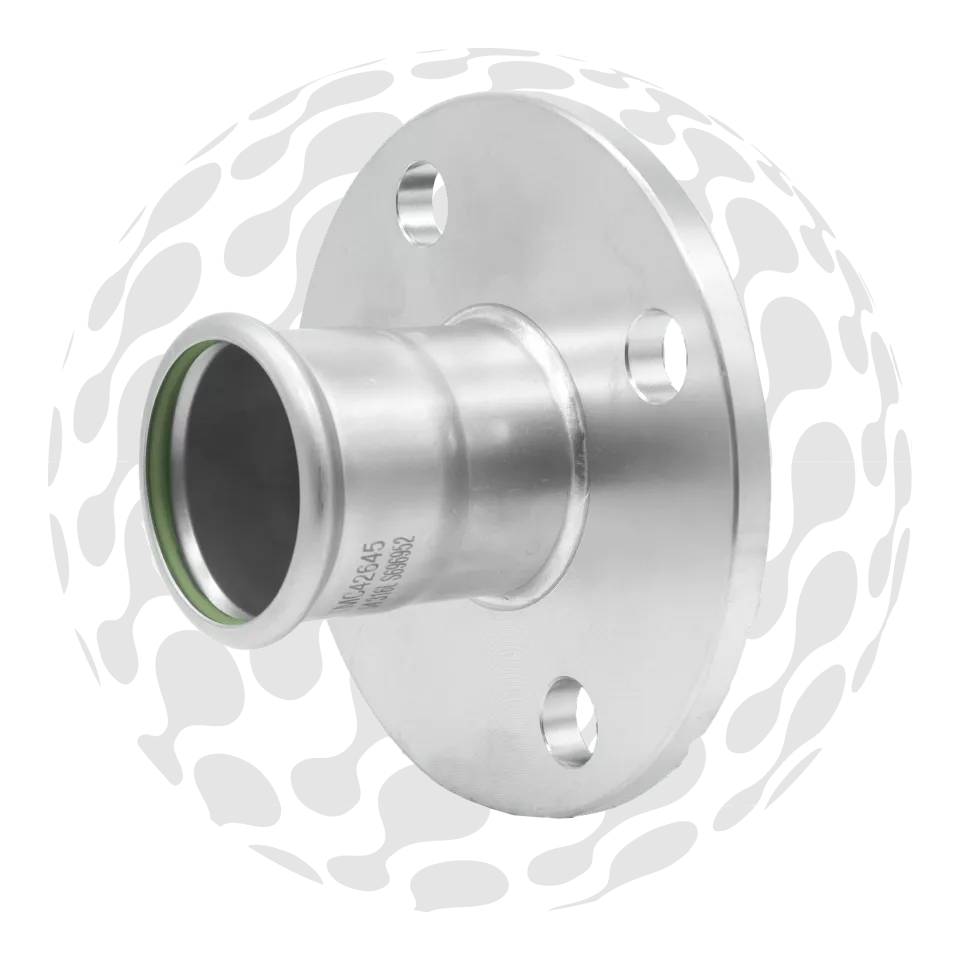

Our raised face flange are only stocked in full thickness. Raised face flanges are good for high pressure environments as the pressure concentrates on the raised face rather than the main face. We stock these for pipe in ANSI150 & PN16.

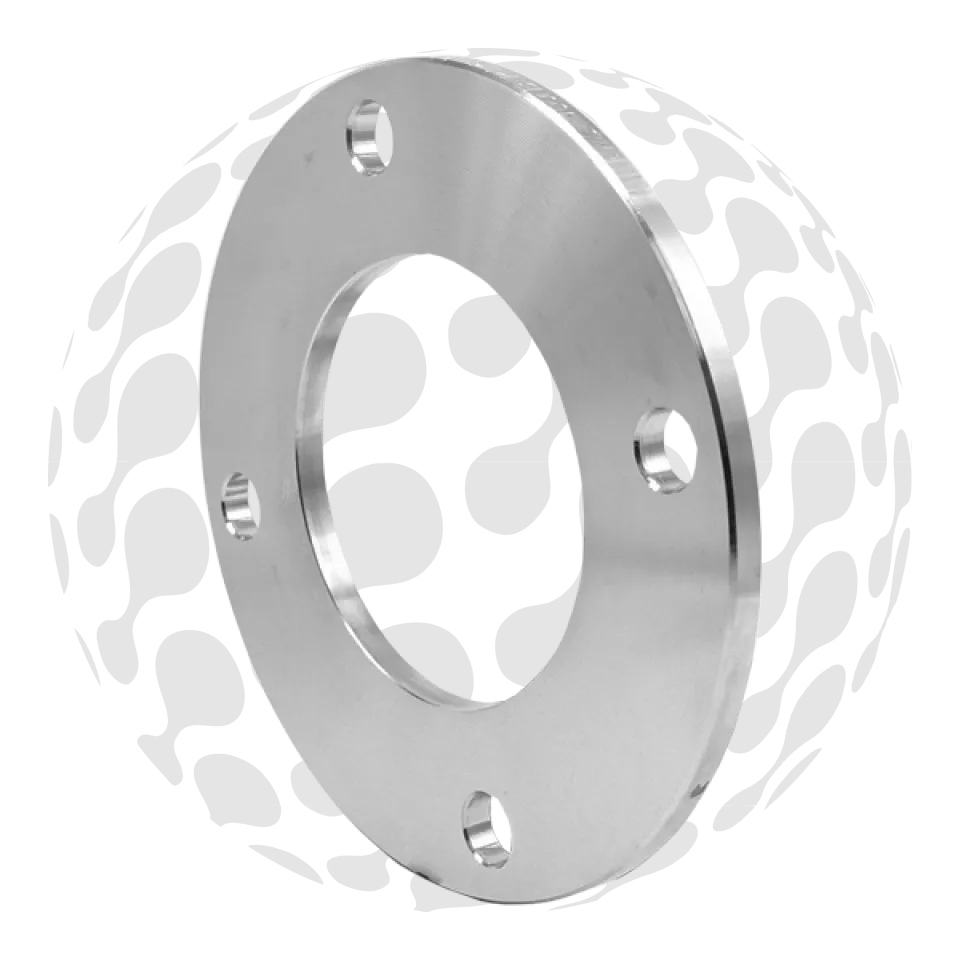

This is a blank flange. There is no internal hole in the centre. It is used to blank off tube and pipe flanges to stop the flow at the end of a flanged pipe run or if there are plans for further expansion. If needed, they can also be bored out to suit different tube or pipe sizes depending on your application. We have them available in Table E, Table D, PN10-16 and Ansi150.

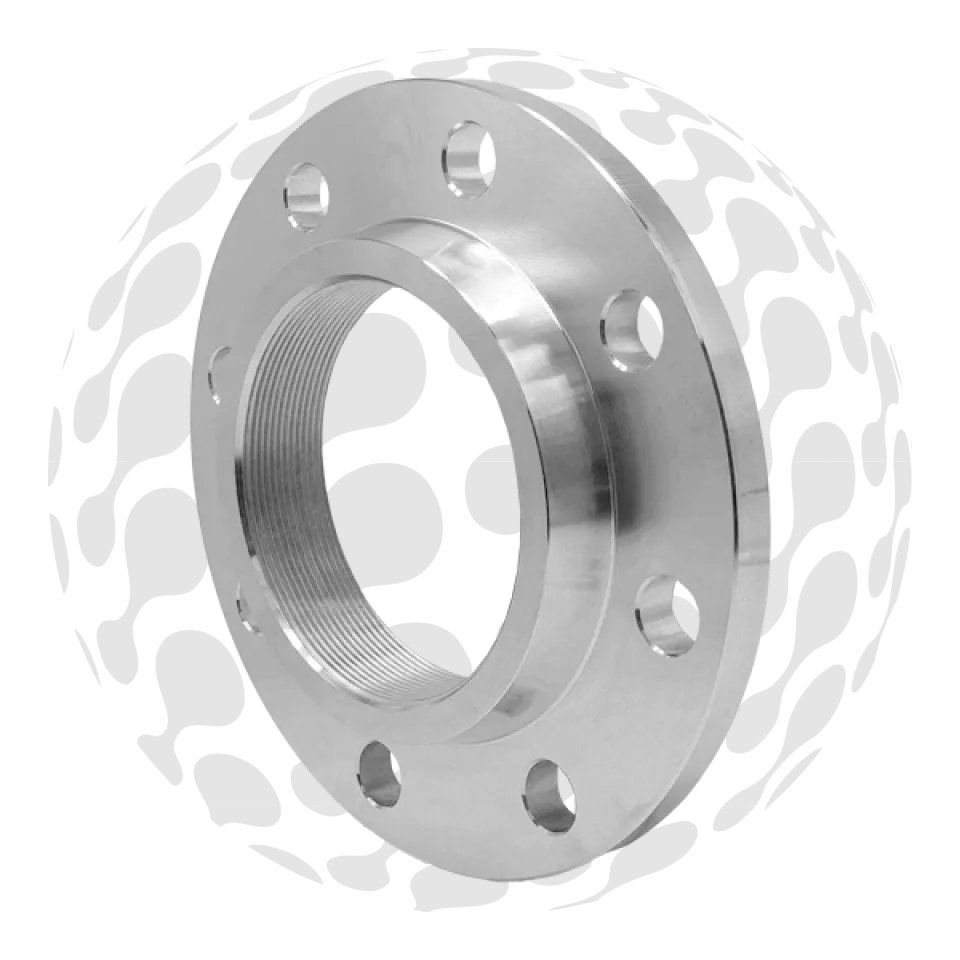

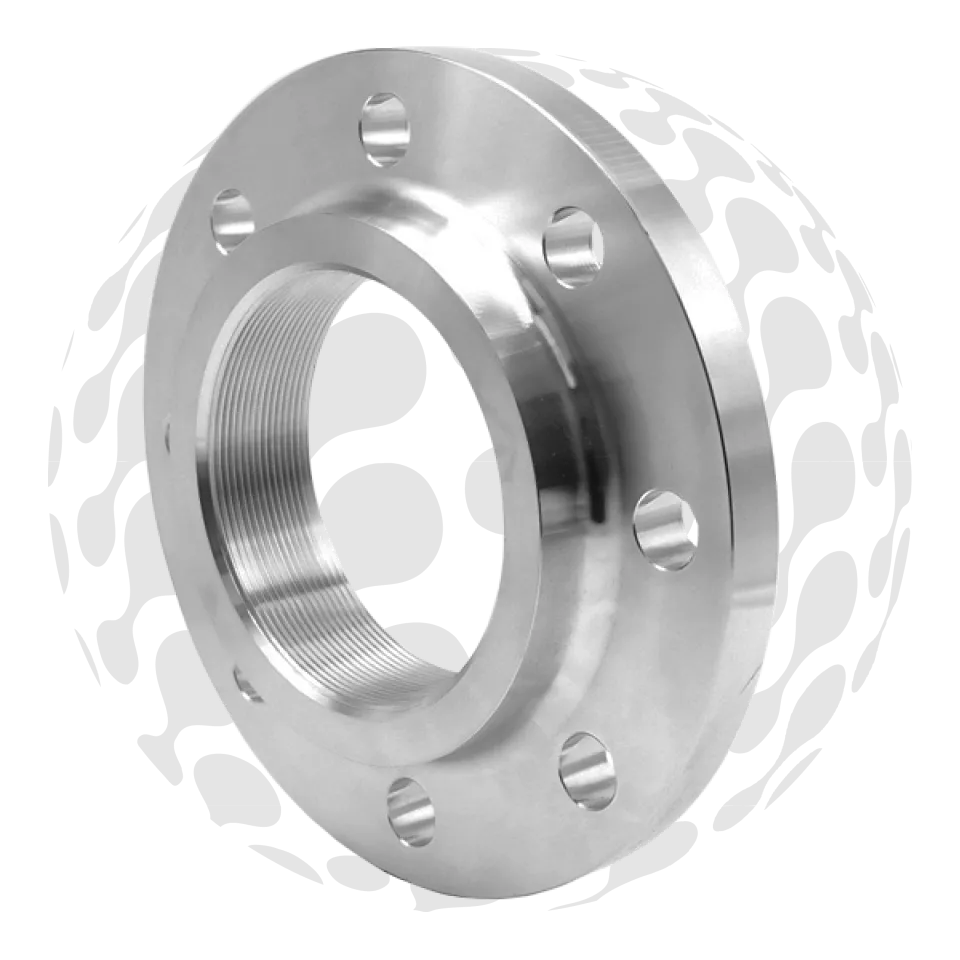

BSP Threaded flange are used for bsp threaded applications. Here you will see a raised face on one side and an internal female parallel BSP Thread in the centre. The thread size is always the same size as the flange size and we have them available for Table E, Ansi150 and PN10-16. For other sizes TMC can custom make these flanges by boring the internal of a blank flange and welding in a socket.

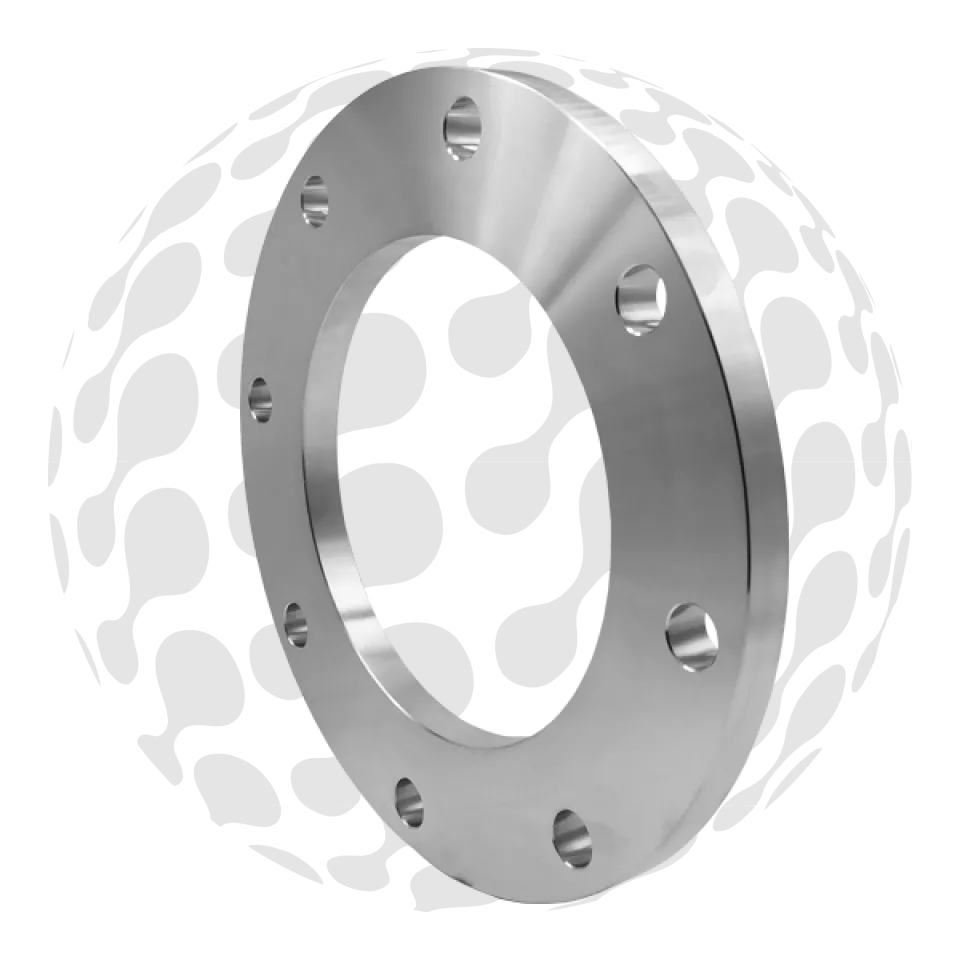

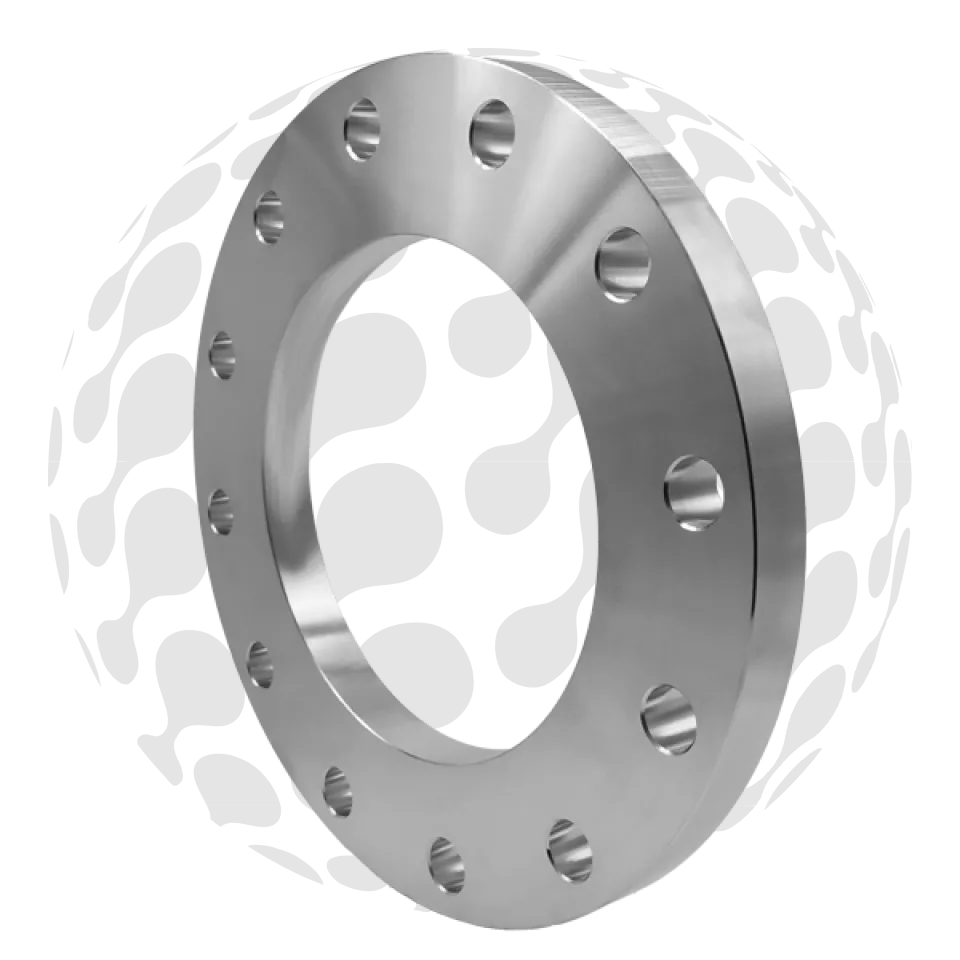

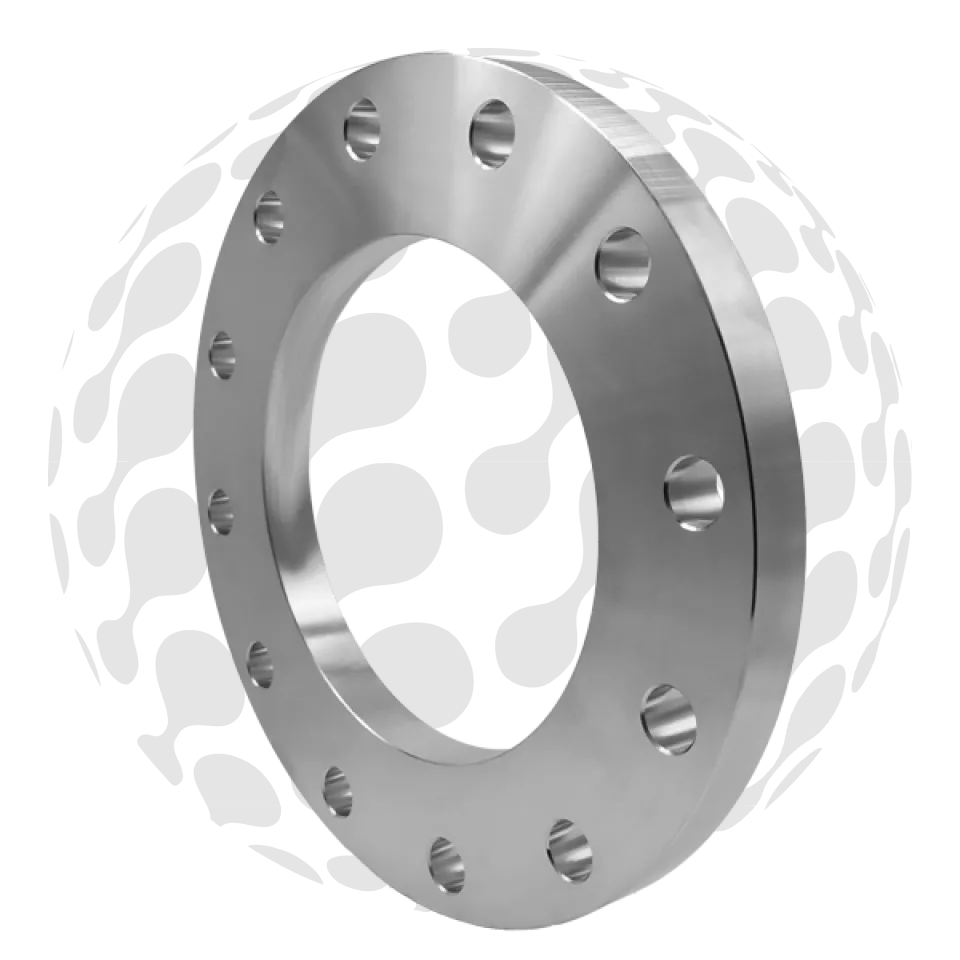

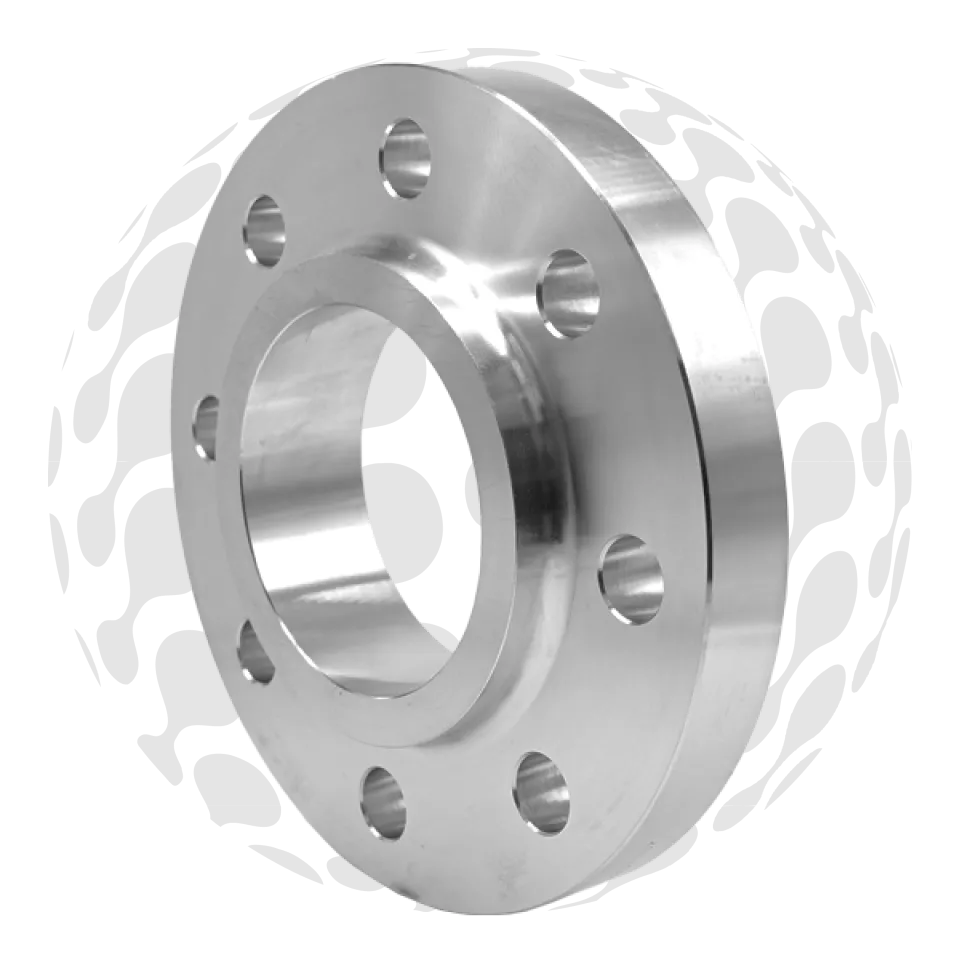

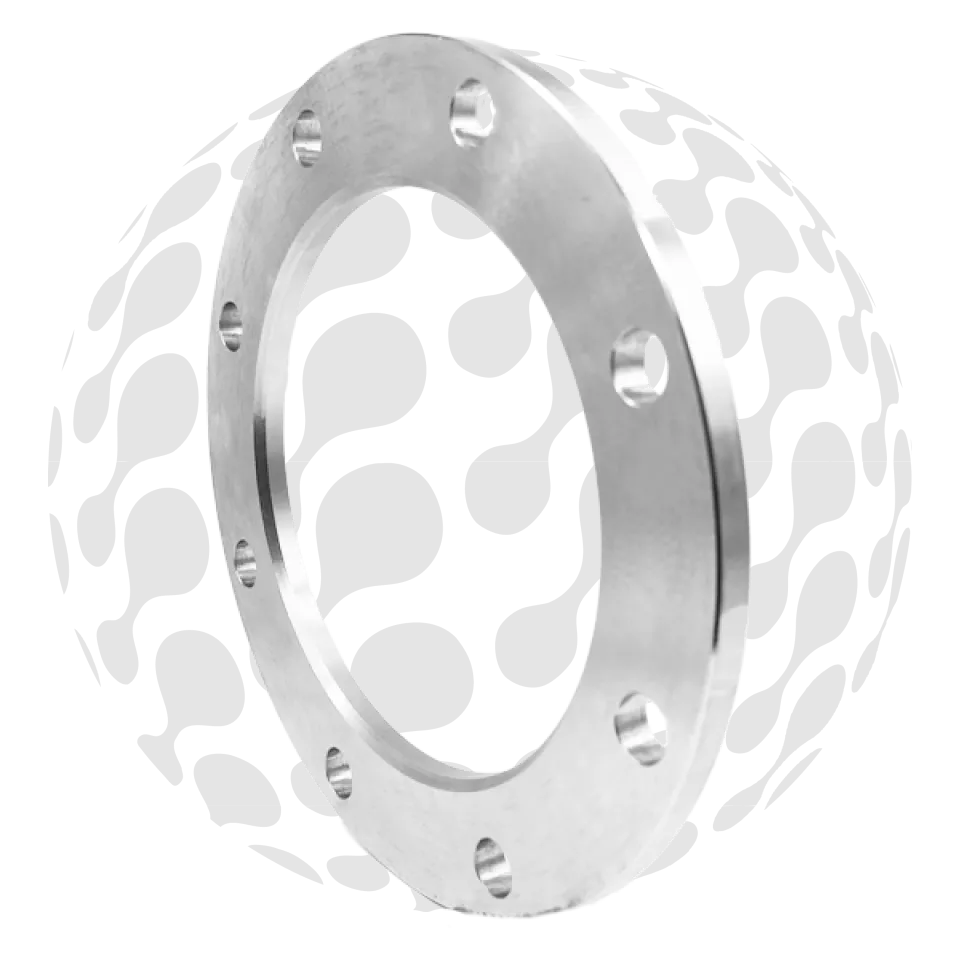

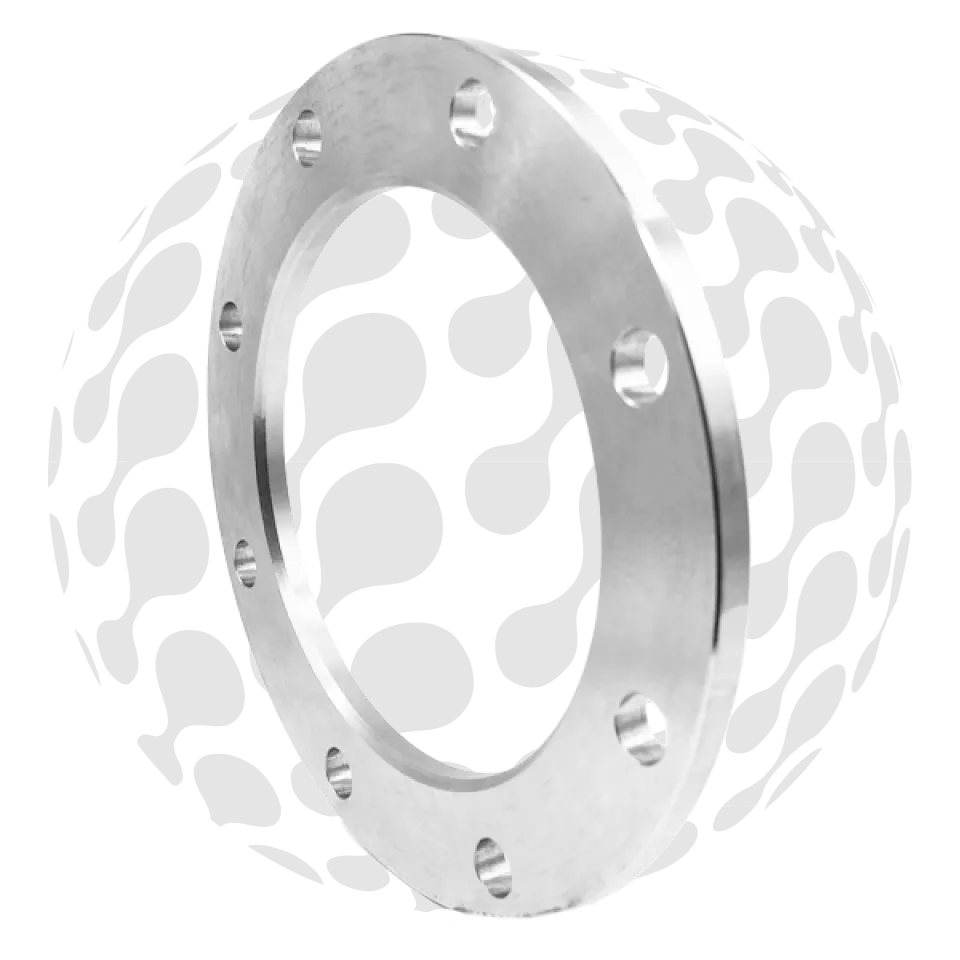

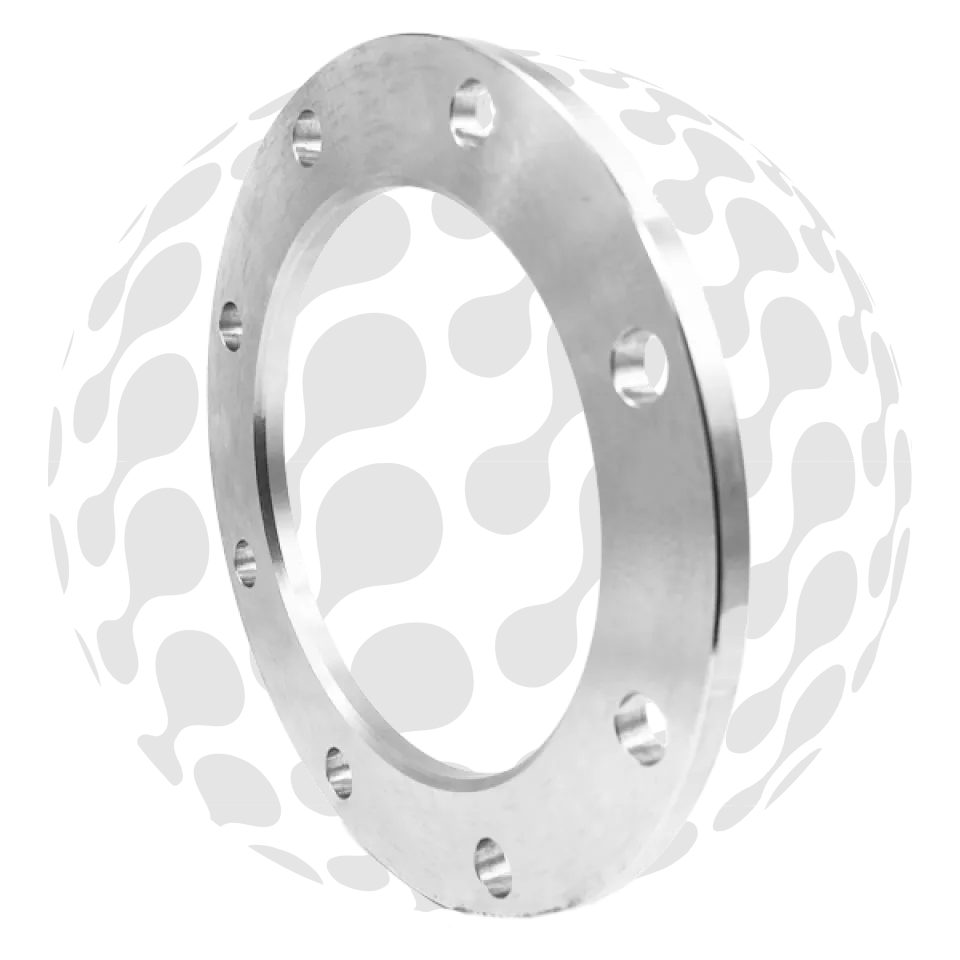

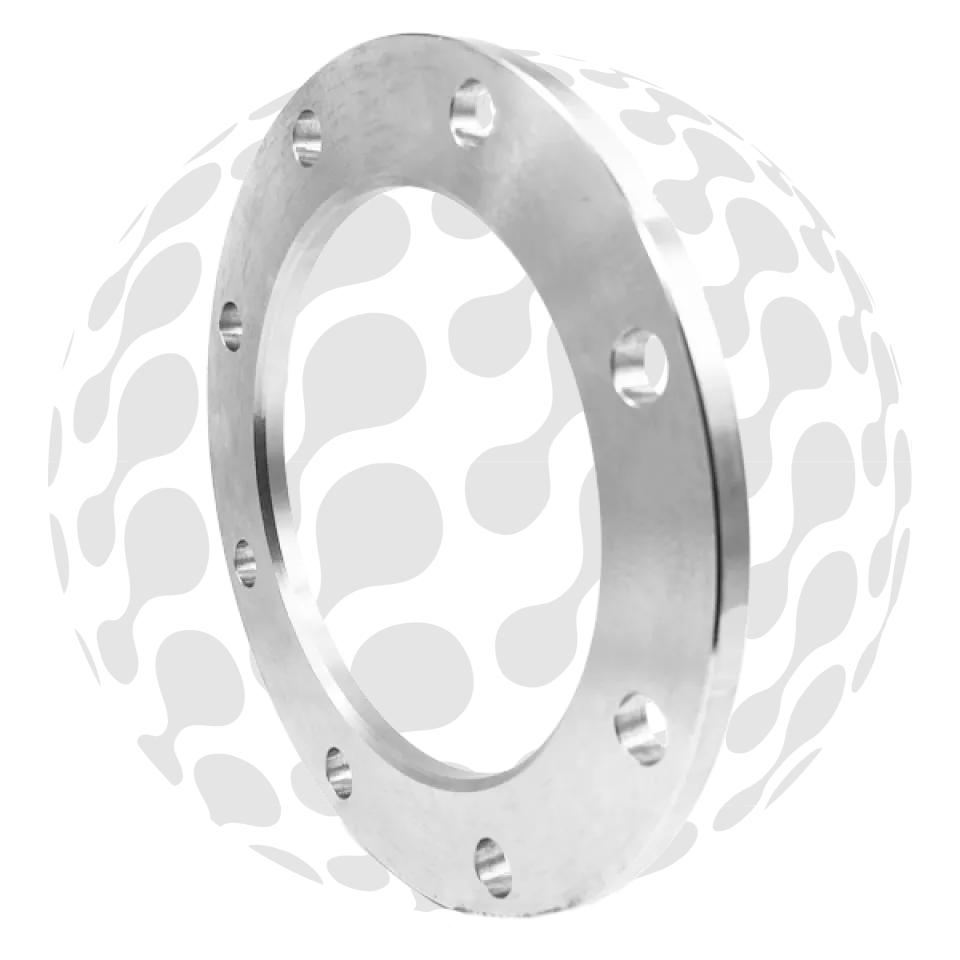

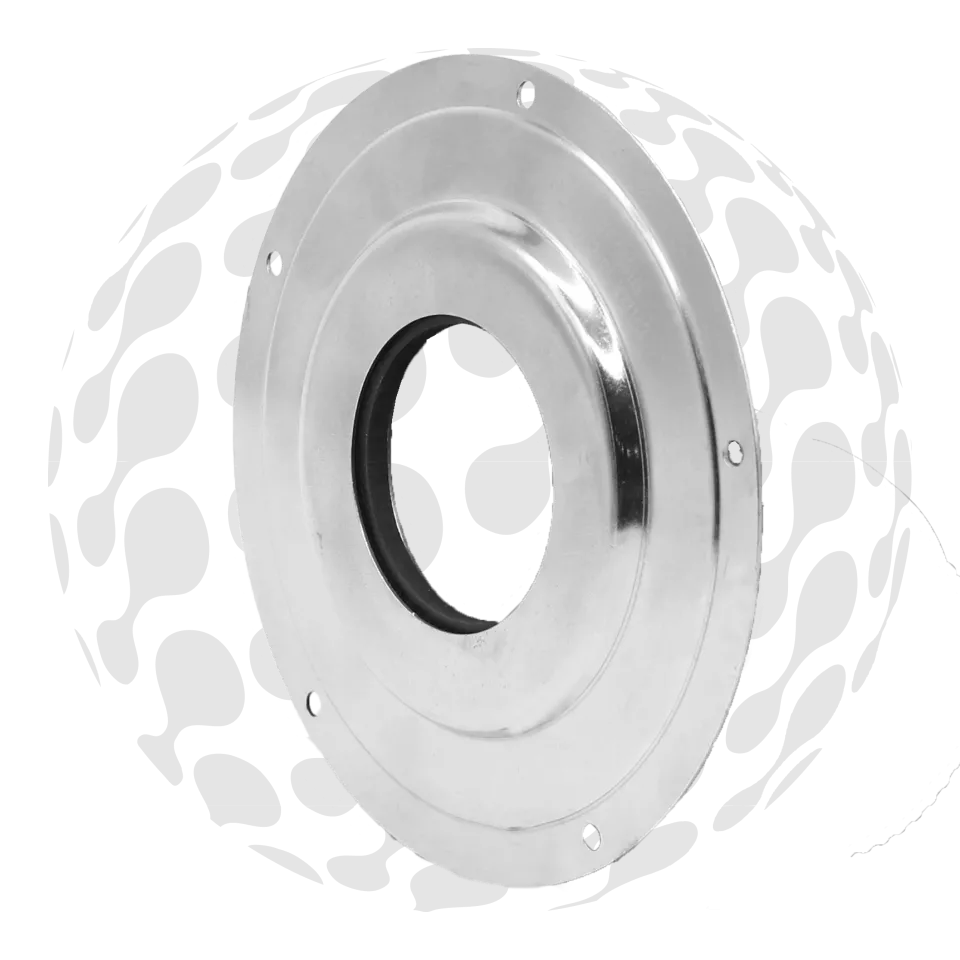

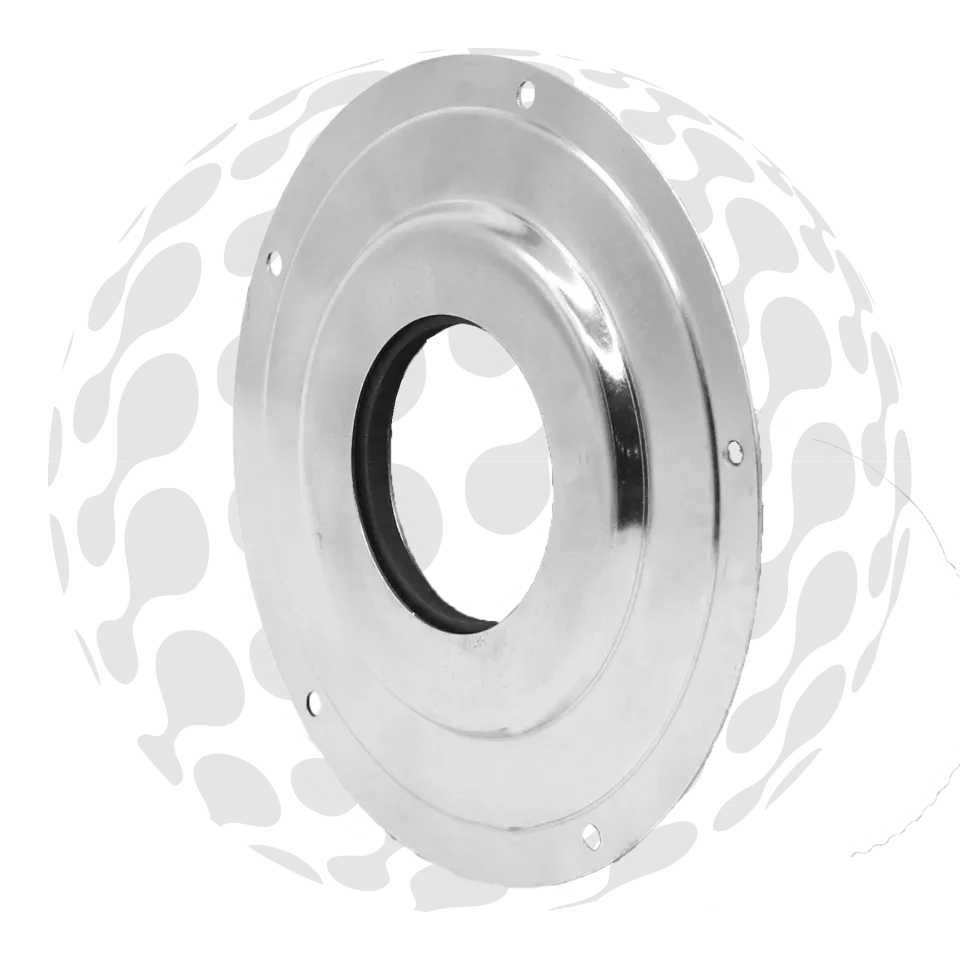

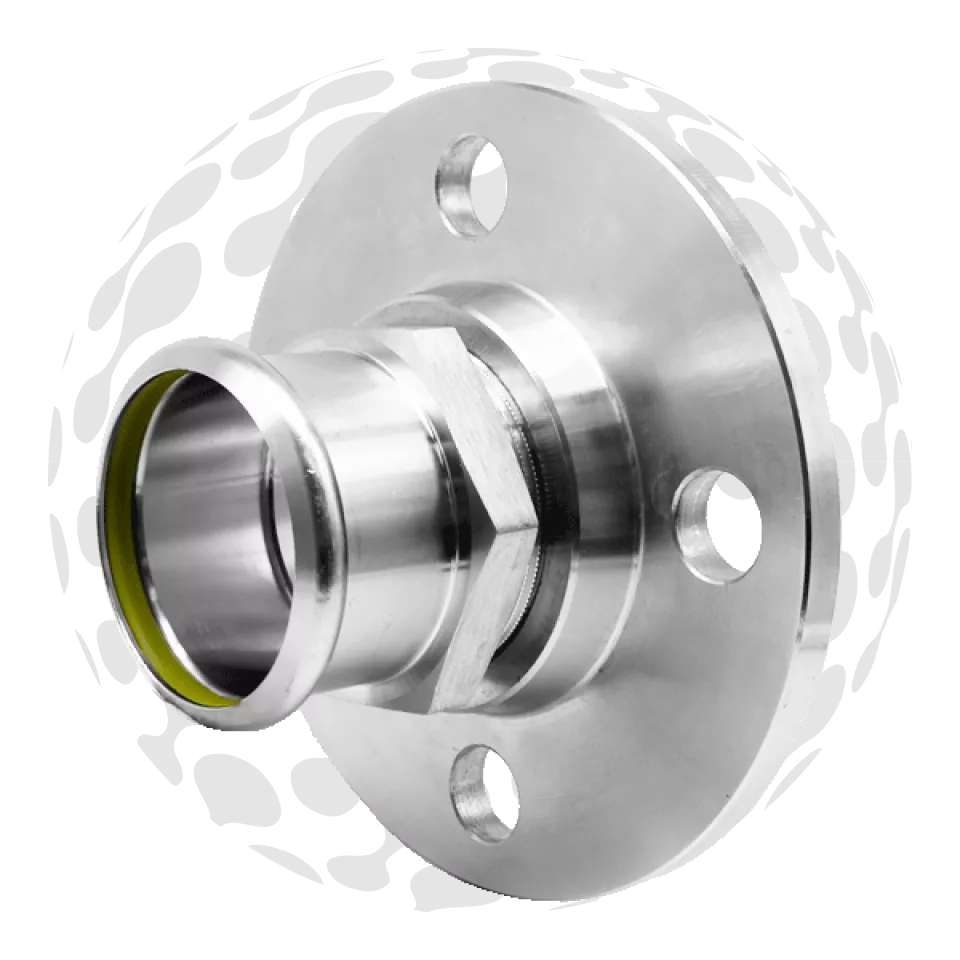

Back up flanges, otherwise known as floating flanges, are used with pipe stub ends or tube neck rings. These are great as in certain applications it makes your installation a lot quicker/easier because you can just swivel the flange to the right orientation to match the boltholes of whatever you are bolting the flange to. For all flanges, we stock bolts and bolt kits. We stock these in Table E, Table D, PN10, PN10-16, ANSI150.

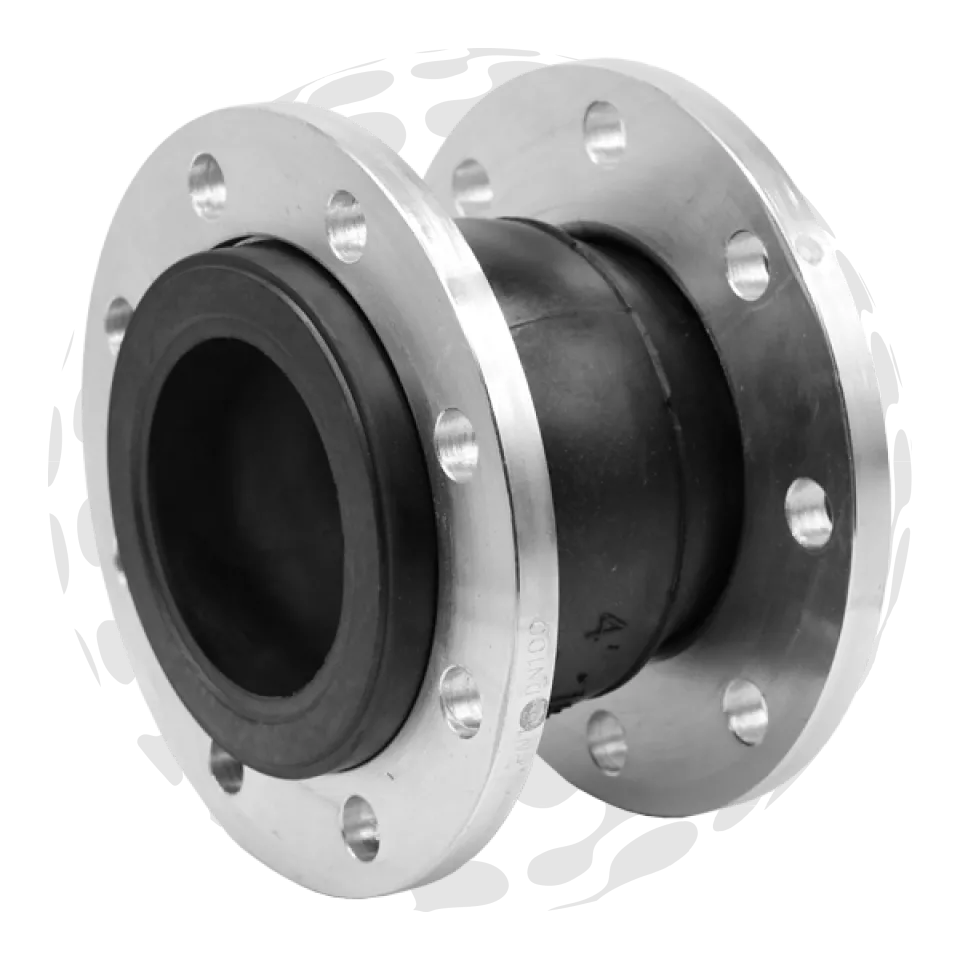

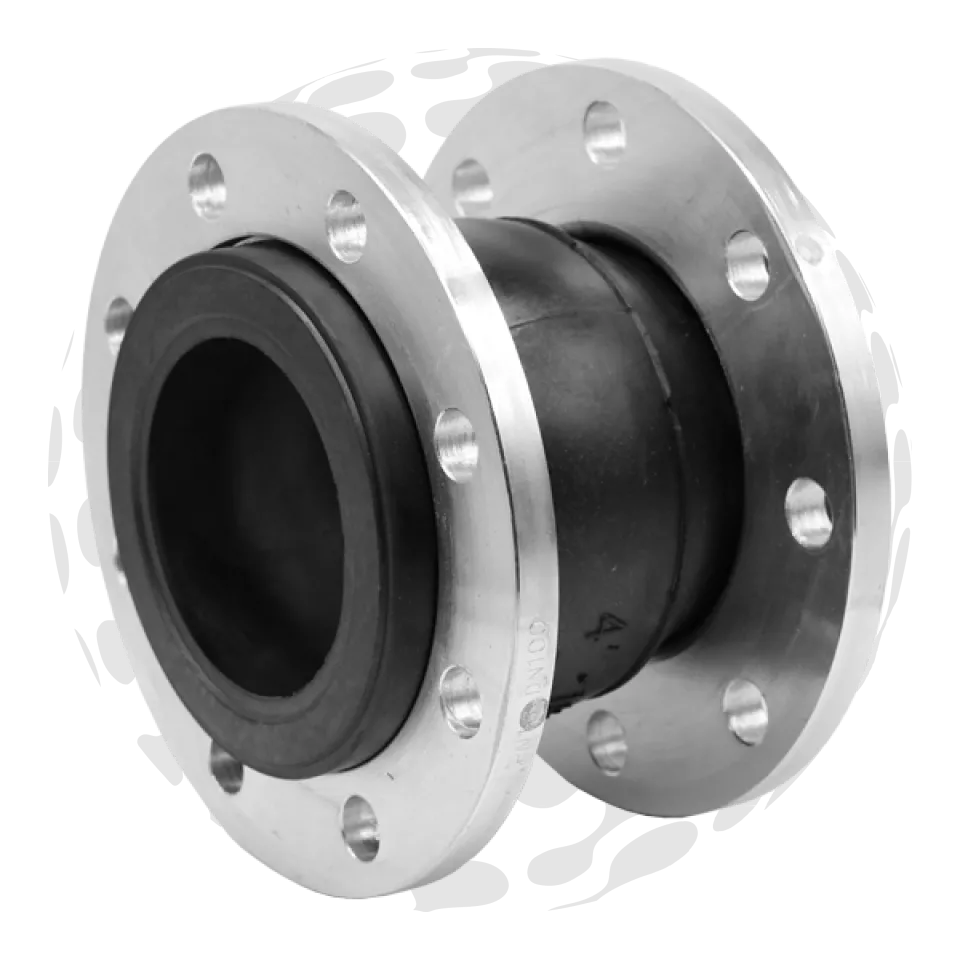

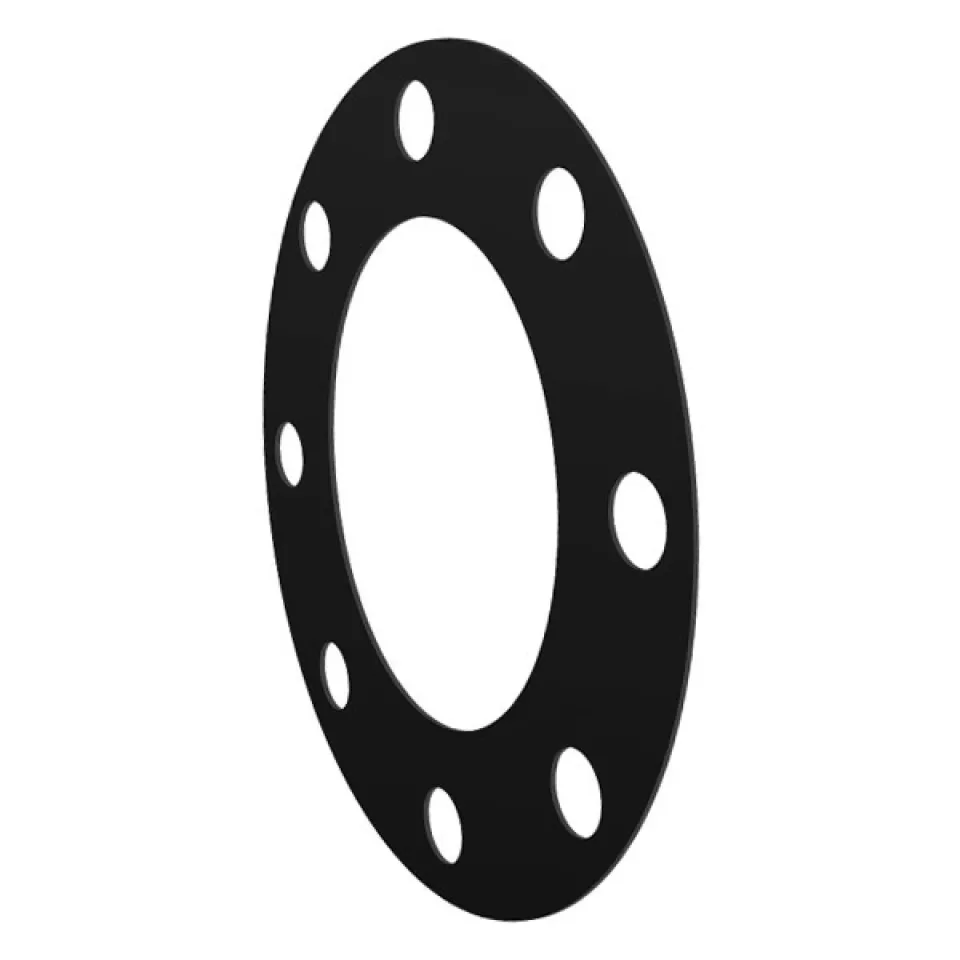

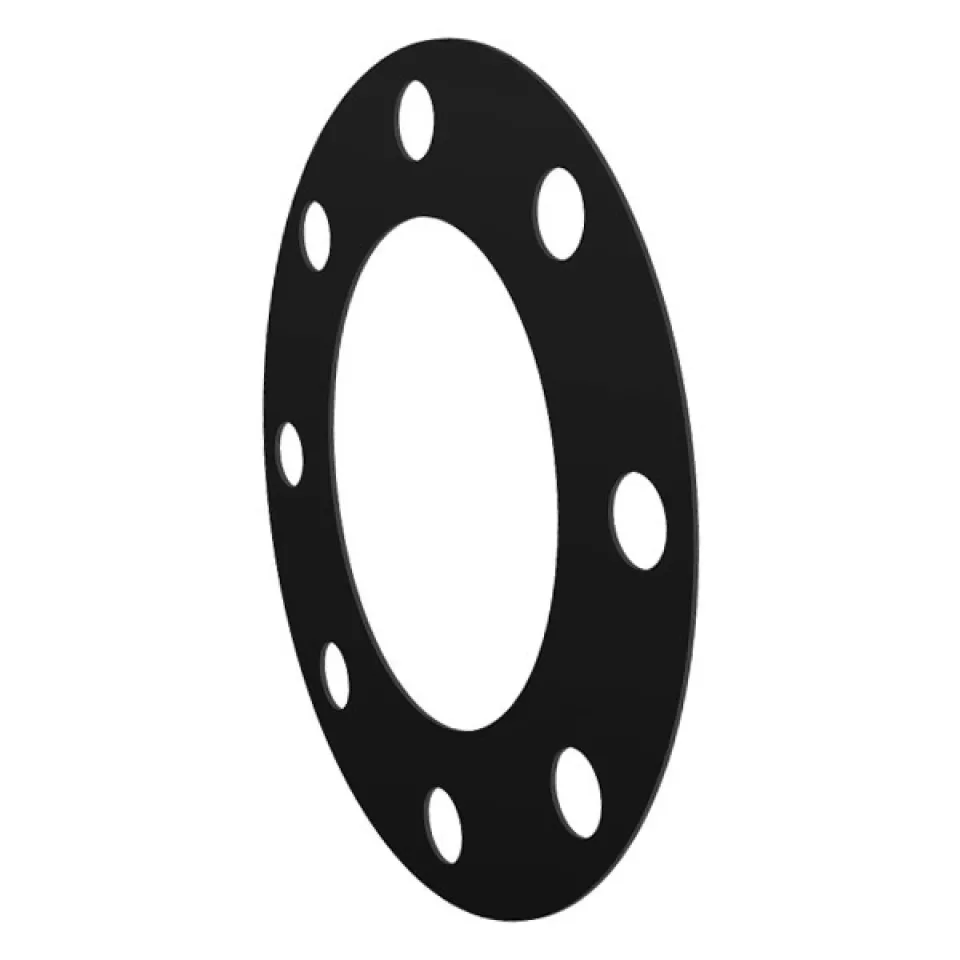

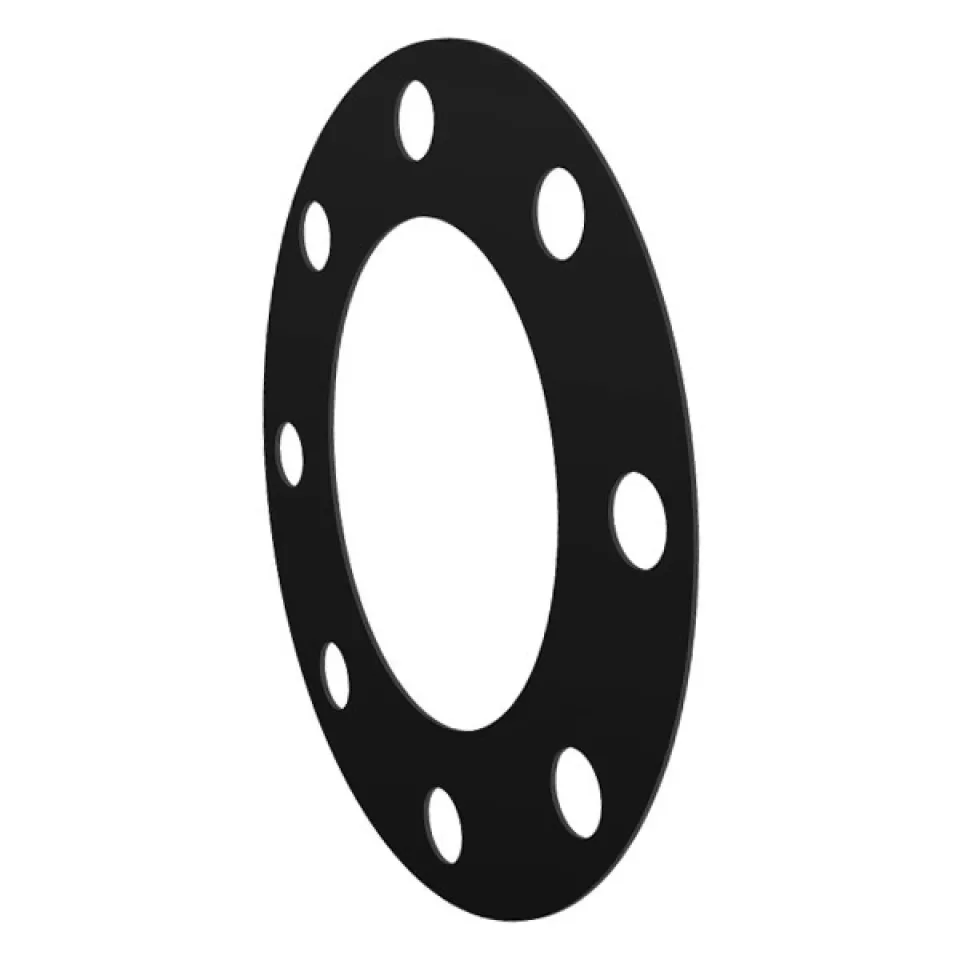

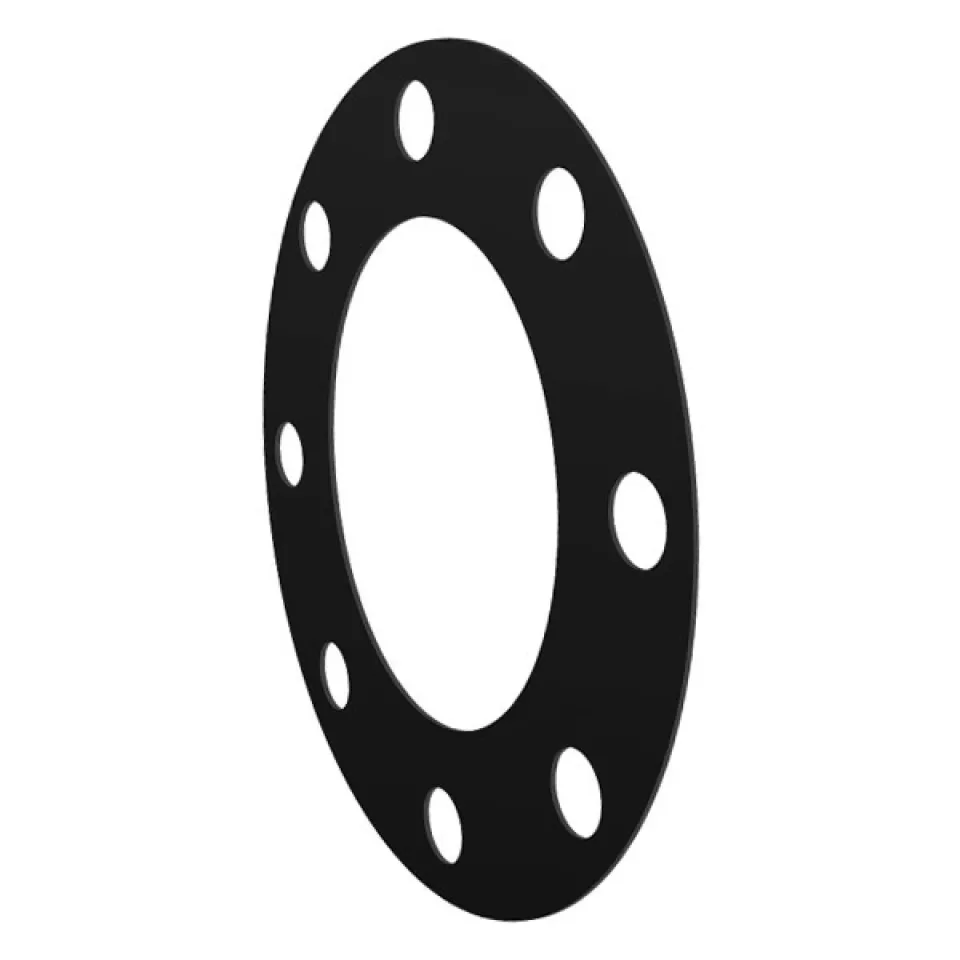

Flange gaskets create a static seal between two flange faces, designed to keep liquids and gases from seeping out. The black gasket is made from insertion rubber and can handle up to 70 degrees. The white gasket is made from nitrile and can handle temperatures up to 90 degrees. Nitrile gaskets are typically used in food and beverage applications.

Related Products

Learn about Stainless Steel and discover more about how we can help you with supply in your engineering business.

Watch the latest videos from The Metal Company to learn all about how our products and services can help you. We Make buying stainless steel easy.

More Videos About Flanges

Our Range of Flanges

The Metal Company’s range of flanges includes the Tube Flanges, Pipe flanges, BSP threaded flanges, Backup Flanges, and blind flanges.

Flanges are available in various sizes and standards to suit imperial tube, schedule pipe and spiral welded tube. Typical industry applications include irrigation, pumping, petrochemical, geothermal, marine and food & beverage process lines. The Metal Company stock flanges in both Full Thickness & Lightweight thickness to suit your application.

Flanges are used to connect pipes, valves, pumps and other equipment to form a piping system. Flanges also provide easy access for cleaning, inspection or modification.

Flat faced slip on flanges are smooth on both sides of the flange. It slips over either tube or pipe and then is welded into place. It is available for both tube and pipe to suit standards for Table E, Table D, PN10-16, ANSI150, PN16 and AS4087 for pipe.

Our raised face flange are only stocked in full thickness. Raised face flanges are good for high pressure environments as the pressure concentrates on the raised face rather than the main face. We stock these for pipe in ANSI150 & PN16.

This is a blank flange. There is no internal hole in the centre. It is used to blank off tube and pipe flanges to stop the flow at the end of a flanged pipe run or if there are plans for further expansion. If needed, they can also be bored out to suit different tube or pipe sizes depending on your application. We have them available in Table E, Table D, PN10-16 and Ansi150.

BSP Threaded flange are used for bsp threaded applications. Here you will see a raised face on one side and an internal female parallel BSP Thread in the centre. The thread size is always the same size as the flange size and we have them available for Table E, Ansi150 and PN10-16. For other sizes TMC can custom make these flanges by boring the internal of a blank flange and welding in a socket.

Back up flanges, otherwise known as floating flanges, are used with pipe stub ends or tube neck rings. These are great as in certain applications it makes your installation a lot quicker/easier because you can just swivel the flange to the right orientation to match the boltholes of whatever you are bolting the flange to. For all flanges, we stock bolts and bolt kits. We stock these in Table E, Table D, PN10, PN10-16, ANSI150.

Flange gaskets create a static seal between two flange faces, designed to keep liquids and gases from seeping out. The black gasket is made from insertion rubber and can handle up to 70 degrees. The white gasket is made from nitrile and can handle temperatures up to 90 degrees. Nitrile gaskets are typically used in food and beverage applications.

Related Products

More Videos About Flanges

More Videos

You Ask, We Answer

Do you have questions regarding stainless steel, our products or our service? We would love to hear your suggestions for videos we could make.