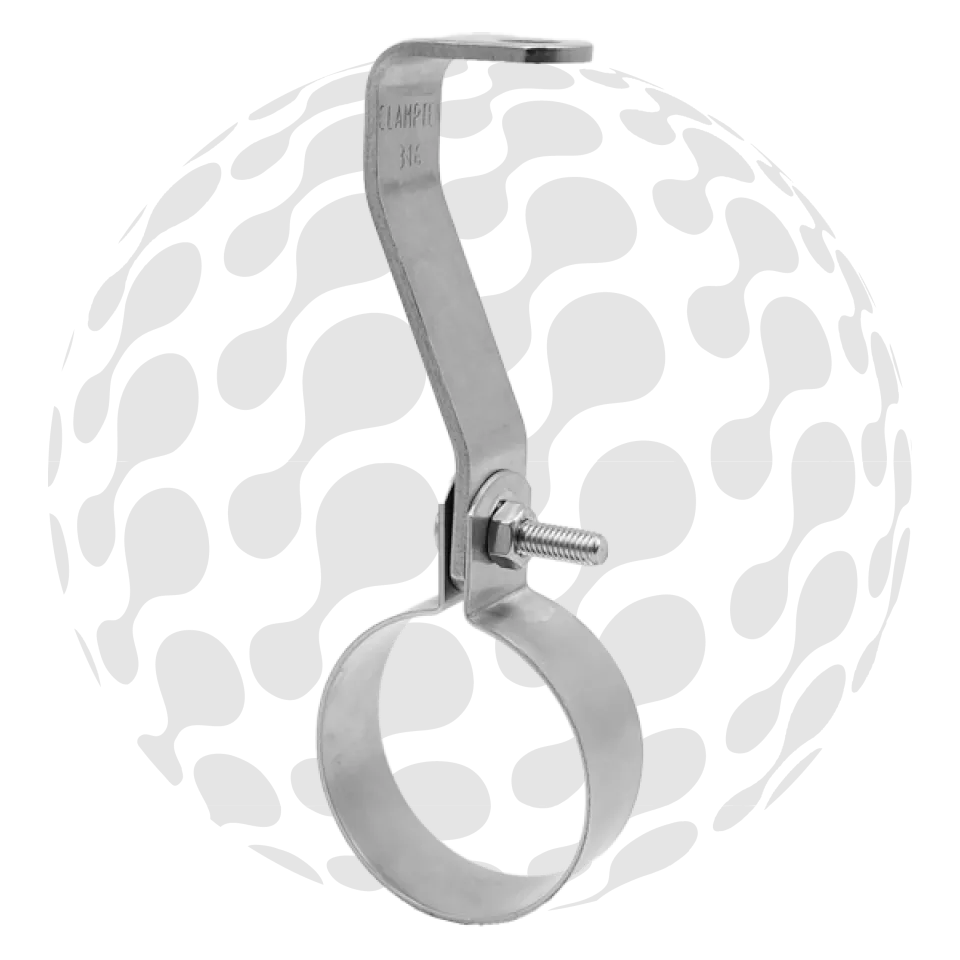

The Metal Company have a range of clamps to suit different work-spaces and pipework. These are used to hold tube and pipe in a rigid position away from surfaces to allow for easy cleaning and insulation.

About

Clamps are typically used in piping & architecture, food and beverage, pumping, agriculture and machinery and flexible piping.

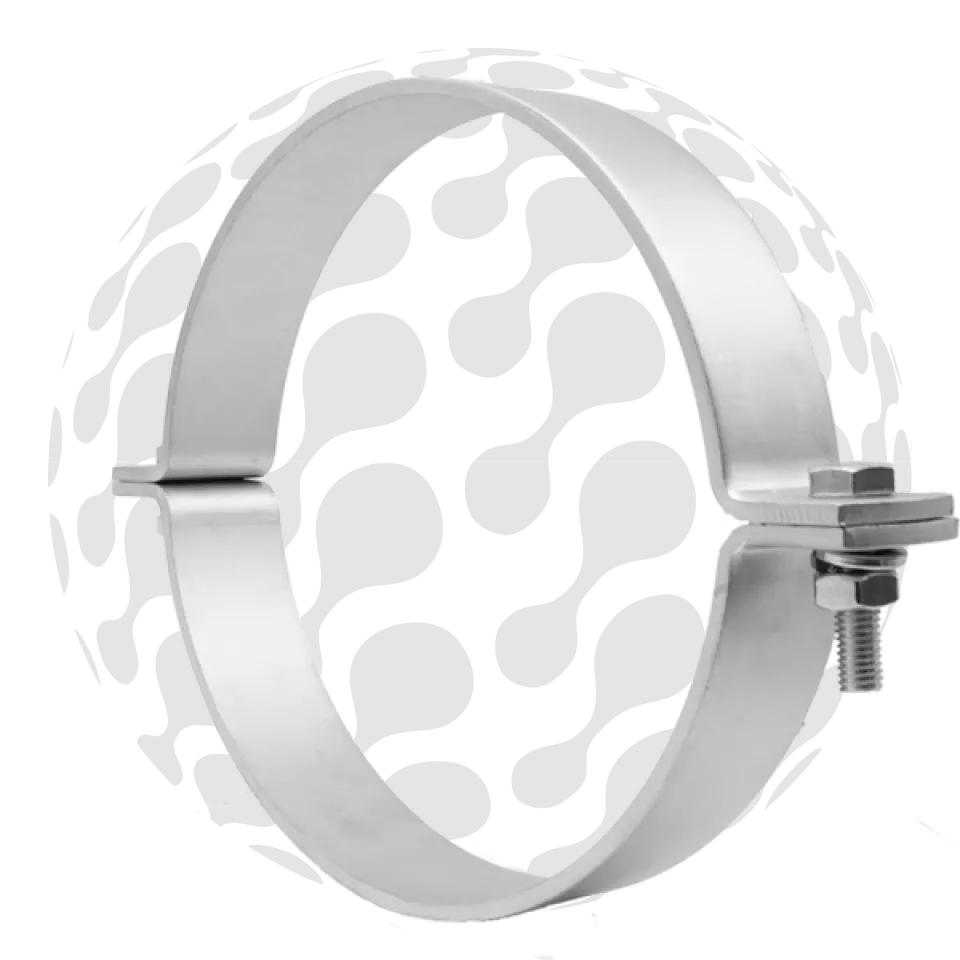

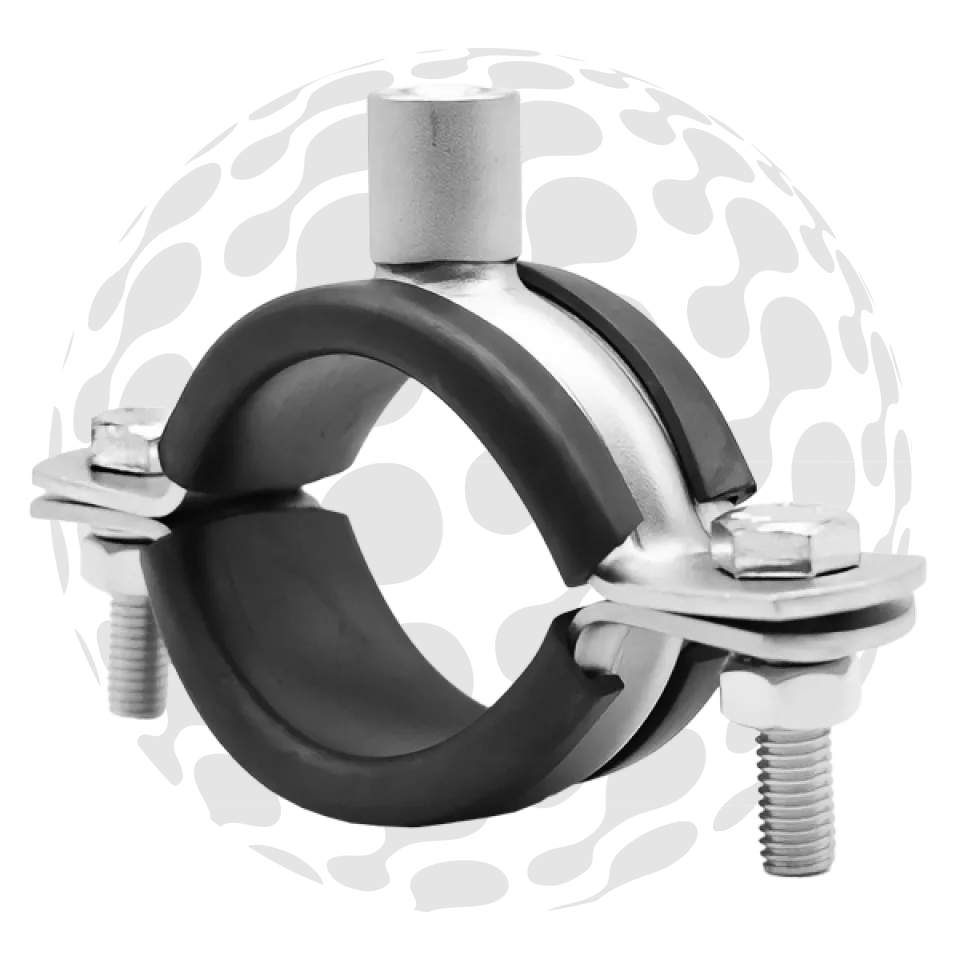

These are used to hold tube and pipe in a rigid position away from surfaces to allow for easy cleaning and insulation. They can come as saddles or clamps. Clamps have a hinge on one side and the bolt on the other. Clamps work well in space for pipe works in condensed situations.

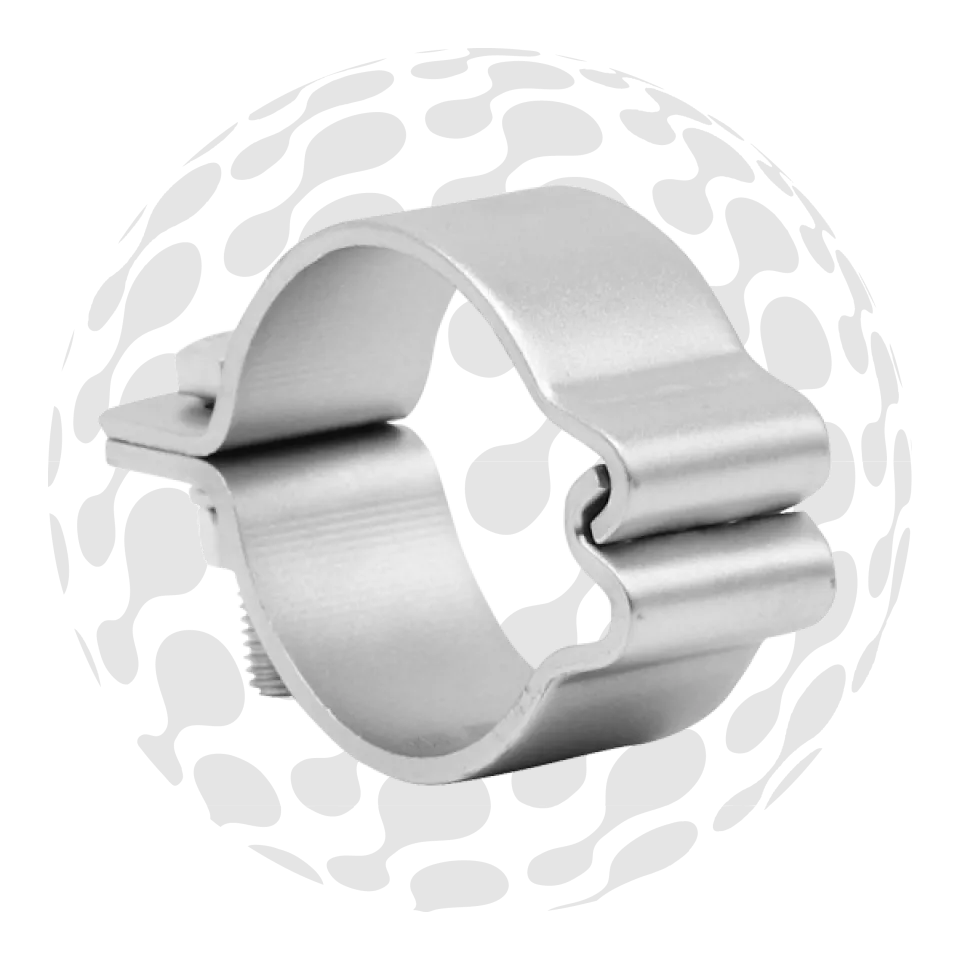

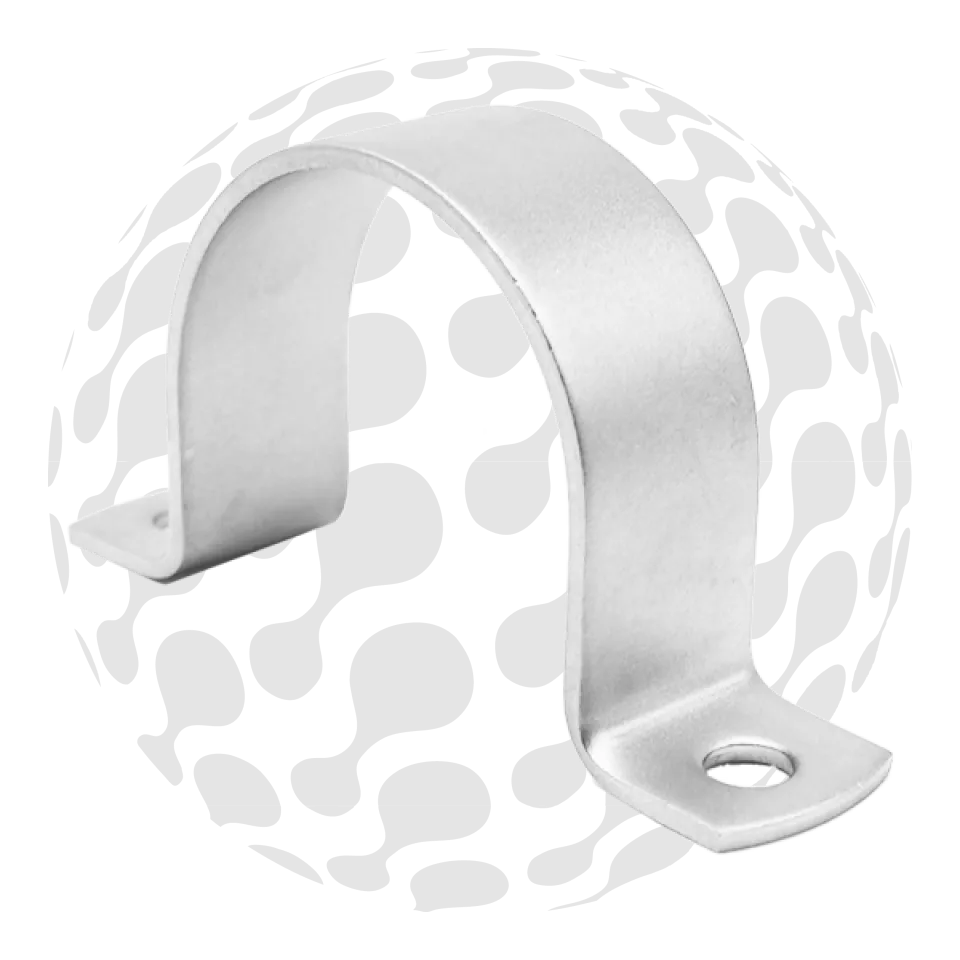

With saddles, they have a bolt on either side. Saddles replace clamps in smaller sizes where the hinge of a clamp becomes unfeasible as well as in larger sizes where the saddle provides a stronger solution.

Clamps are stocked from sizes 1″(25.4) to 4″ (101.6) and sizes less than 1″ and more than 4″ are stocked as a saddle.

Depending on the space of the project or your preference in stabilising the clamp/saddle we have bossed, plain, stubbed and collared.

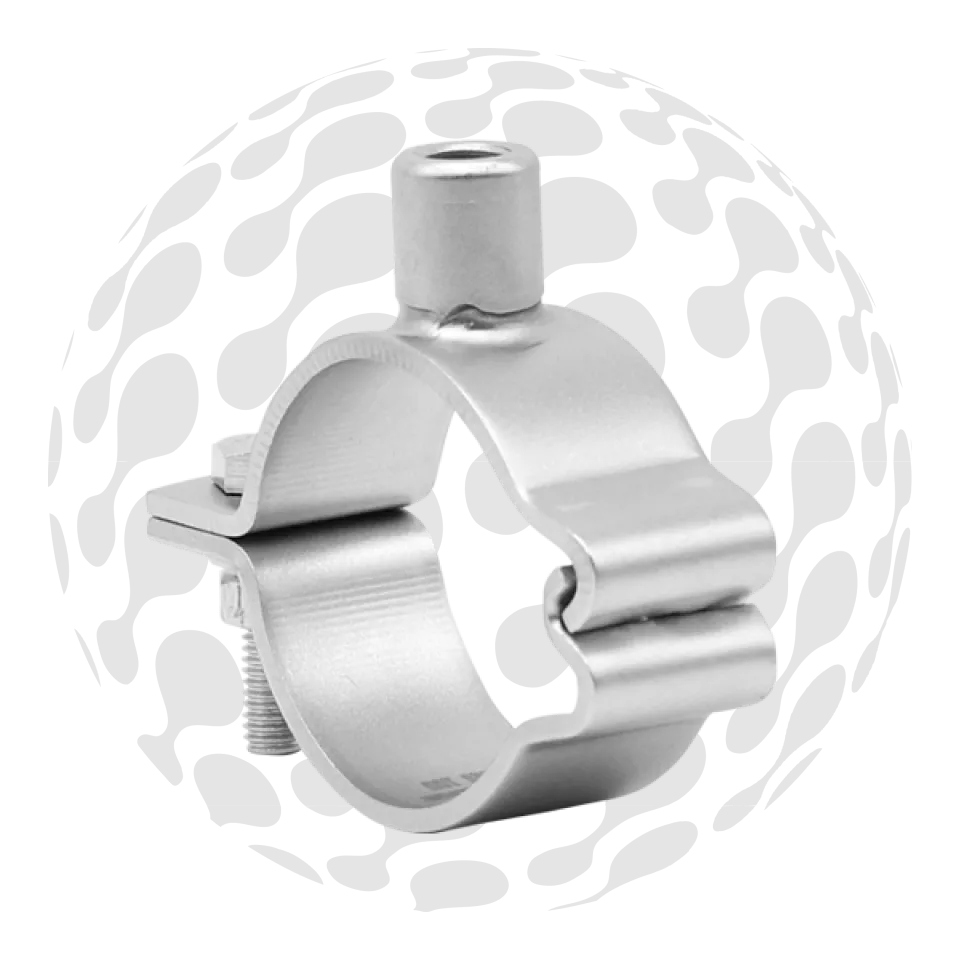

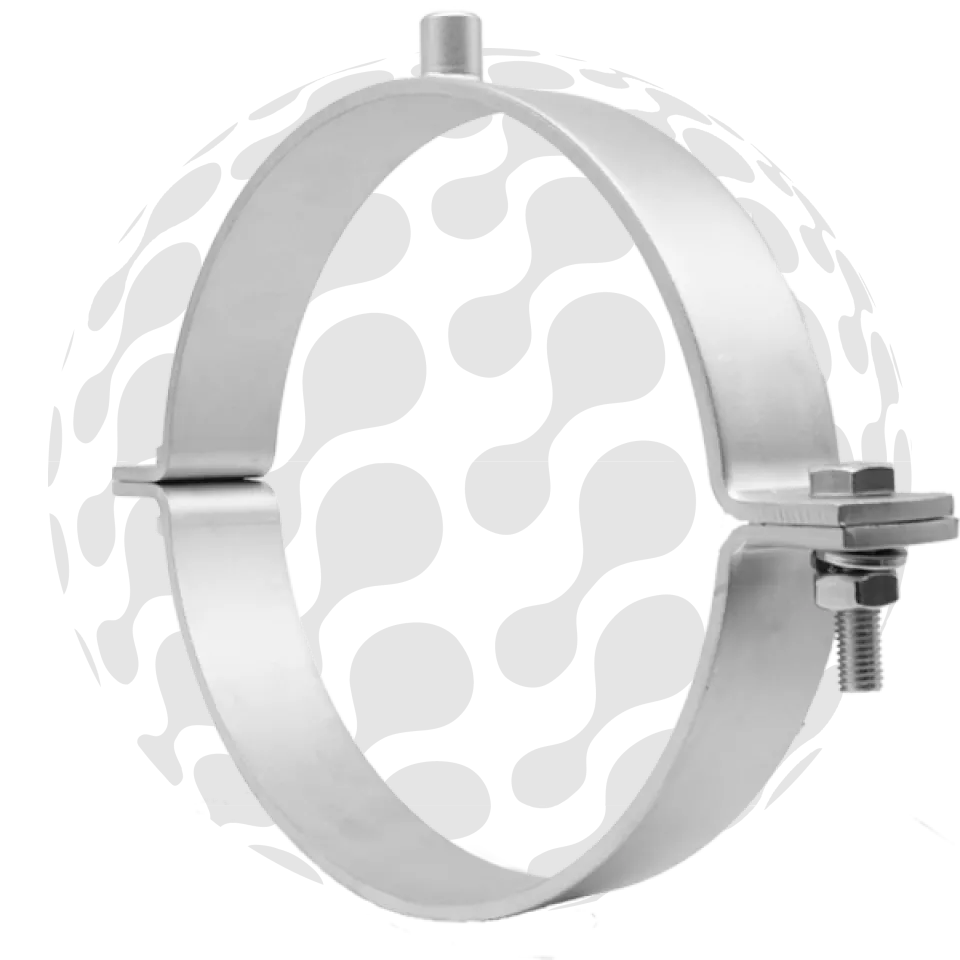

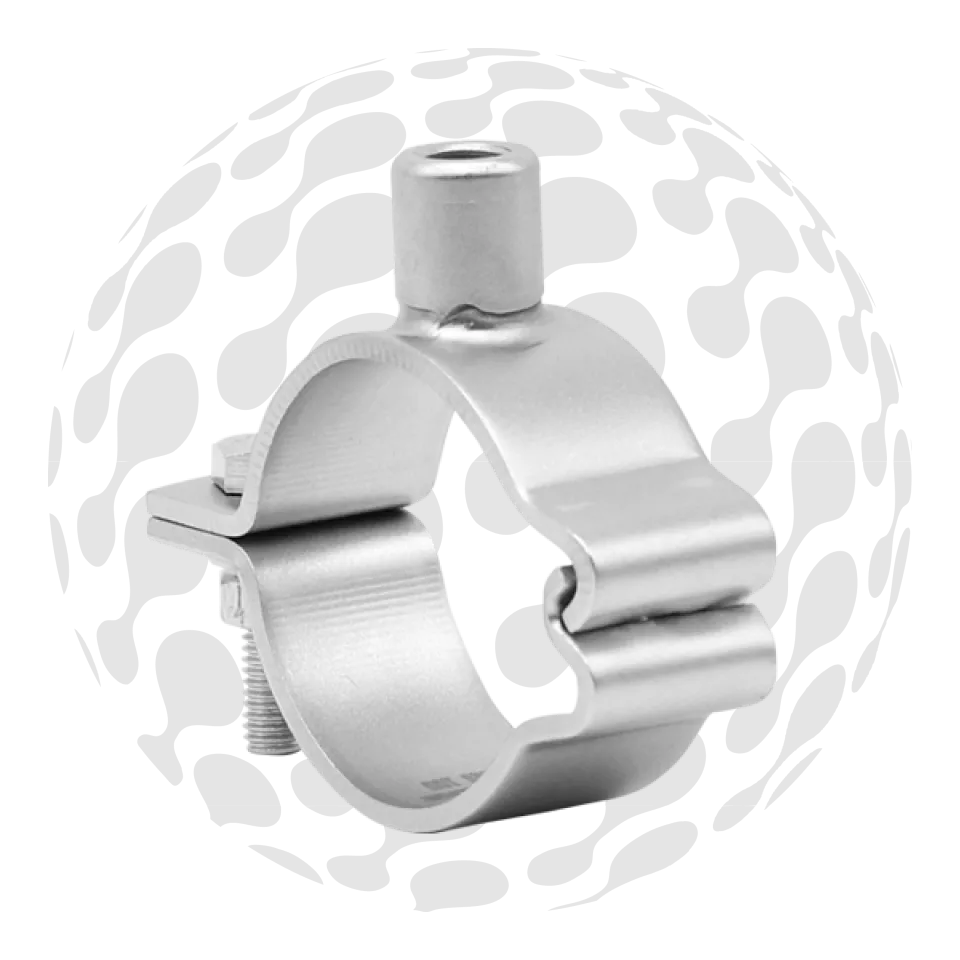

Bossed clamps or saddles feature a 10mm metric female threaded boss in the centre of one clamp half. The boss allows pipework to be secured from a machine, floor, wall or ceiling by threading 10mm metric threaded rod to a bossed wall plate.

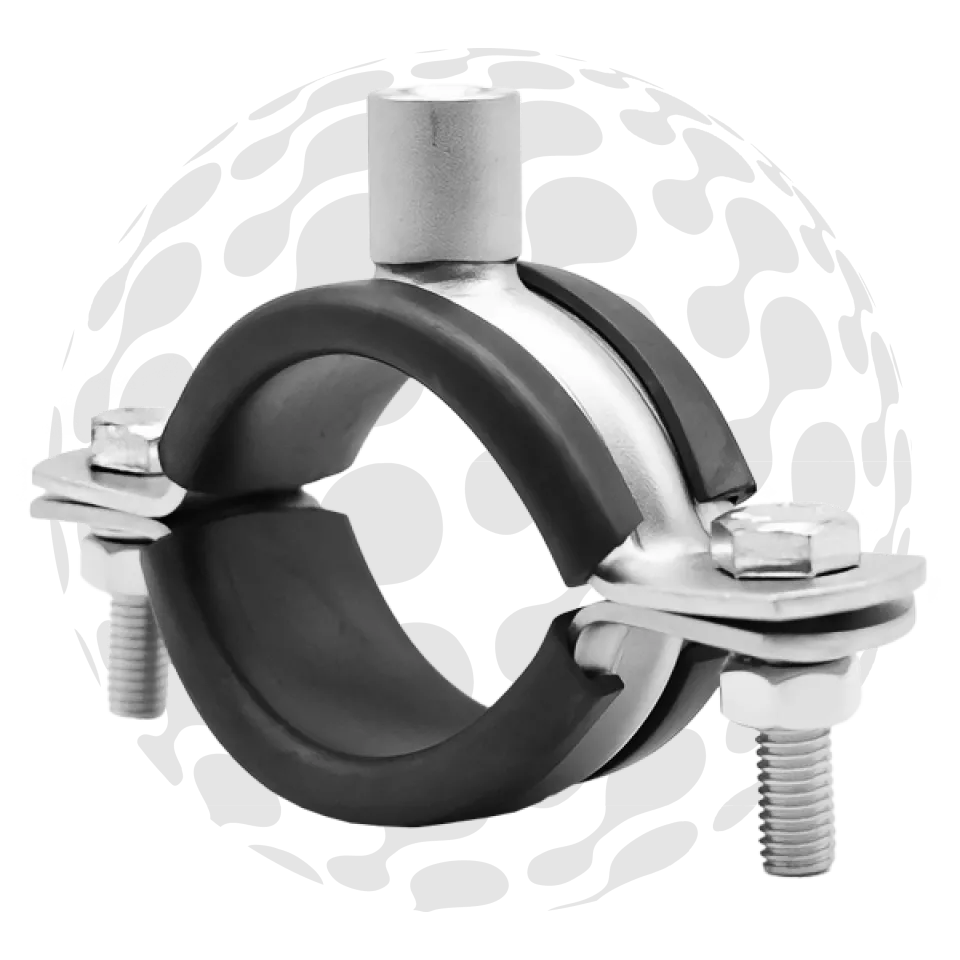

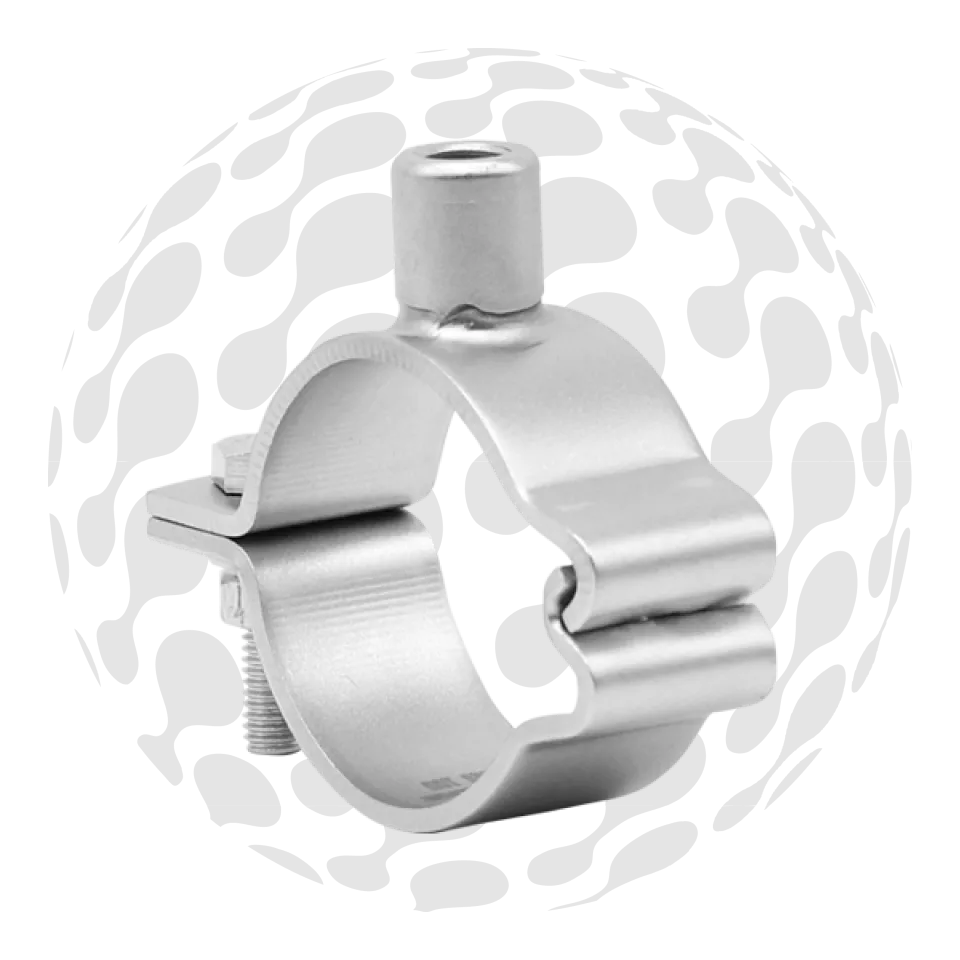

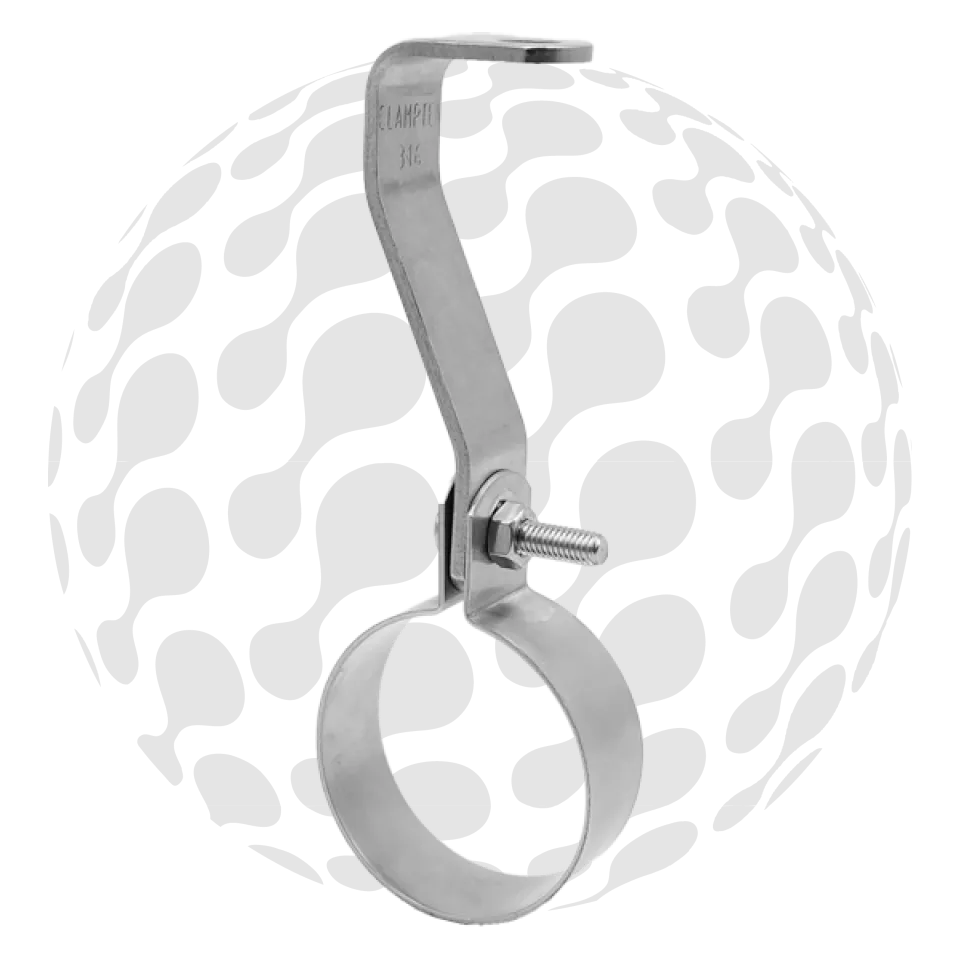

Collared clamps allow a 5/8” or 16mm round bar to be fitted inside a collar or by welding round bar directly to a plain clamp. It is completed with a locking bolt which allows for an easy connect/disconnect.

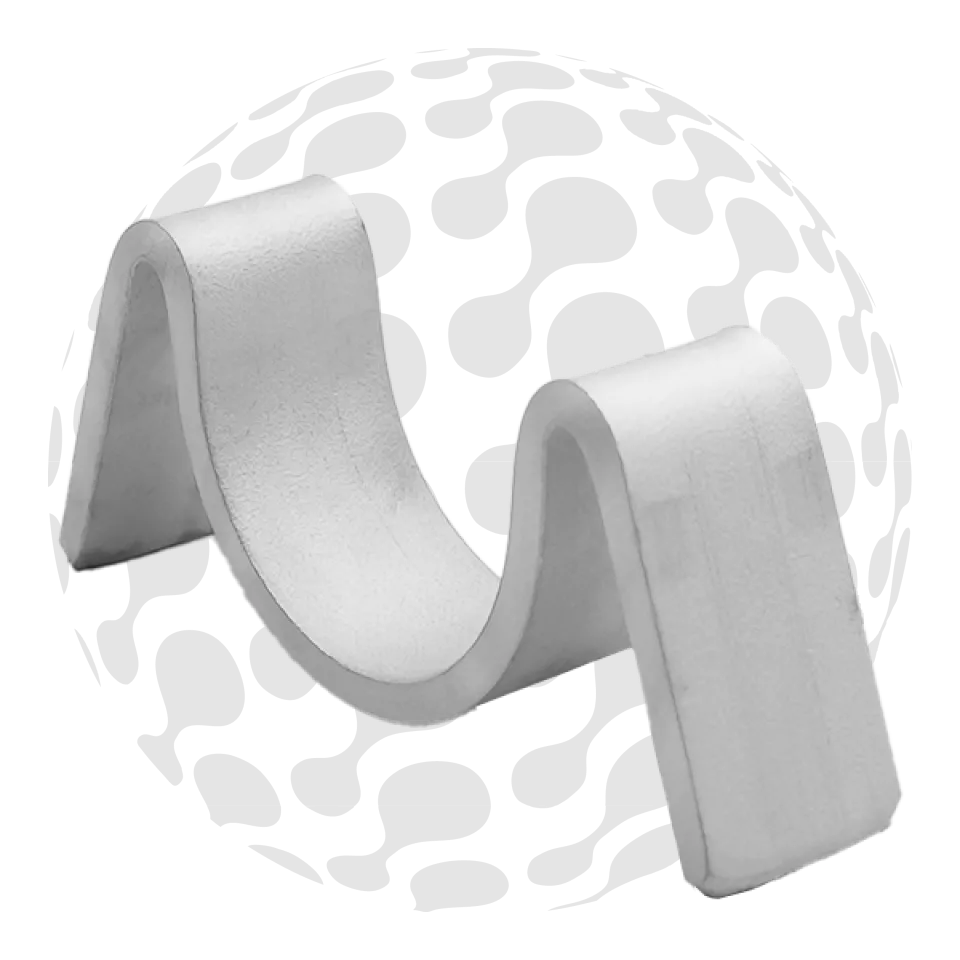

Stubbed clamp is one of our plain tube clamps with a 16mm stainless steel round bar welded at a length of 47mm to the top of it.

We stock clamps and saddles to suit Imperial Tube, Spiral weld Tube, Schedule Pipe and Rapidpress. This can be identified on the inside by a T for tube, P for Pipe or U for Rapidpress.

About

Clamps are typically used in piping & architecture, food and beverage, pumping, agriculture and machinery and flexible piping.

These are used to hold tube and pipe in a rigid position away from surfaces to allow for easy cleaning and insulation. They can come as saddles or clamps. Clamps have a hinge on one side and the bolt on the other. Clamps work well in space for pipe works in condensed situations.

With saddles, they have a bolt on either side. Saddles replace clamps in smaller sizes where the hinge of a clamp becomes unfeasible as well as in larger sizes where the saddle provides a stronger solution.

Clamps are stocked from sizes 1″(25.4) to 4″ (101.6) and sizes less than 1″ and more than 4″ are stocked as a saddle.

Depending on the space of the project or your preference in stabilising the clamp/saddle we have bossed, plain, stubbed and collared.

Bossed clamps or saddles feature a 10mm metric female threaded boss in the centre of one clamp half. The boss allows pipework to be secured from a machine, floor, wall or ceiling by threading 10mm metric threaded rod to a bossed wall plate.

Collared clamps allow a 5/8” or 16mm round bar to be fitted inside a collar or by welding round bar directly to a plain clamp. It is completed with a locking bolt which allows for an easy connect/disconnect.

Stubbed clamp is one of our plain tube clamps with a 16mm stainless steel round bar welded at a length of 47mm to the top of it.

We stock clamps and saddles to suit Imperial Tube, Spiral weld Tube, Schedule Pipe and Rapidpress. This can be identified on the inside by a T for tube, P for Pipe or U for Rapidpress

Videos On Clamps & Saddles

Our Range Of Clamps and Saddles

Clamps and Saddles are used with pipe, tube and RapidPress. Here Wilson will discuss how to identify between Clamps and Saddles, the sizing and range that TMC supply.

What Is the Difference Between Clamps and Saddles? | Technical Tuesday

We stock a range of clamps and saddles to suit Dairy Tube, Metric Press Fit Tube and Schedule Pipe. Watch Huntley discuss the differences between clamps and saddles.

What Does the Wording Inside Our Tube and Pipe Clamps Mean? | Technical Tuesday

We stock clamps to suit tube, schedule pipe and Press-fit metric tube. This can be identified on the inside of the clamp with the letters T for tube, P for pipe and U for Press-fit. Watch Huntley discuss what the wording inside our tube and pipe clamps mean.