Pipe Schedule is the standard method to define the thickness and pressure rating of pipe and is different to the nominal bore.

Typically stainless in New Zealand is available in Schedule 10, Schedule 40 and sometimes in Schedule 80. The higher the schedule number is, the thicker the pipe is and the more pressure it can handle. It is worthwhile to note, the outside diameter of the pipe doesn’t change, only the wall thickness and inside diameter. For example at 50NB, Schedule 10 and schedule 40 both have an OD of 60.33mm but schedule 40 has thicker walls and a smaller Internal Diameter.

All the applicable schedule pipe fittings are manufactured to standard ASME B16.

Schedule pipe typically has a welded seam and is therefore technically non-sanitary. The process to manufacture schedule pipe is referred to as hot rolling which implies rolling stainless steel at high temperatures to form into the desired shape. As the stainless steel cools down the metal can naturally contract, therefore accuracy is difficult to control.

The term NB (Nominal Bore) is often used interchangeably with NPS (Nominal Pipe Size). ‘Nominal’ is a non-dimensional number that identifies the hole diameter. The wall thickness of pipe is determined by the schedule. Pipe fittings are available from The Metal Company in Schedule 10S and Schedule 40S. In the engineering industry, this can also be written or referred to as ‘SCH10’ or ‘S10’ and ‘SCH40’ or ‘S40’.

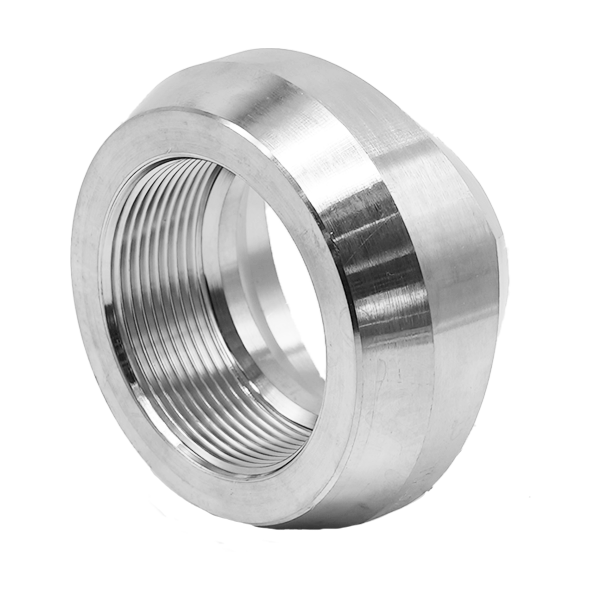

Aside from the pipe fittings range, The Metal Company offers professional schedule pipe fabrication and BSP threading. We have nominated welders able to create customised fittings, providing you with a quick and easy installation on site. Customisation can include extended barrel nipples, extended weld nipples and female BSP threading.

Typical industry applications for schedule pipe and fittings include transporting fluids, gases, drainage & services, irrigation, pumping, petrochemical, geothermal, marine, agriculture and on machinery.