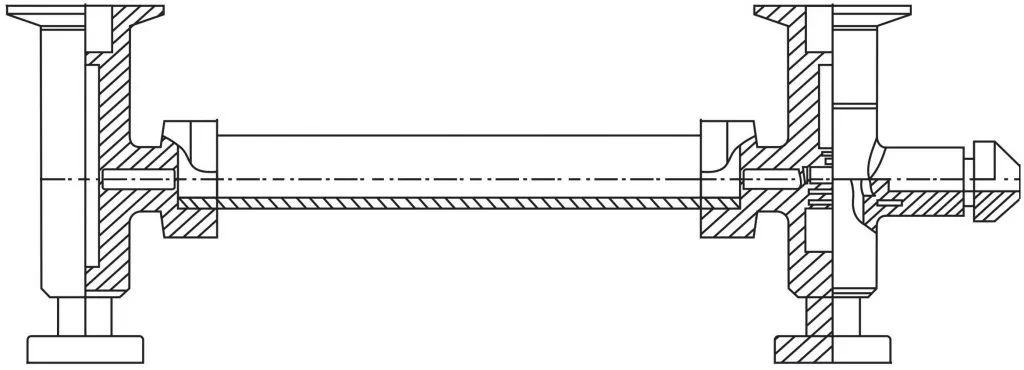

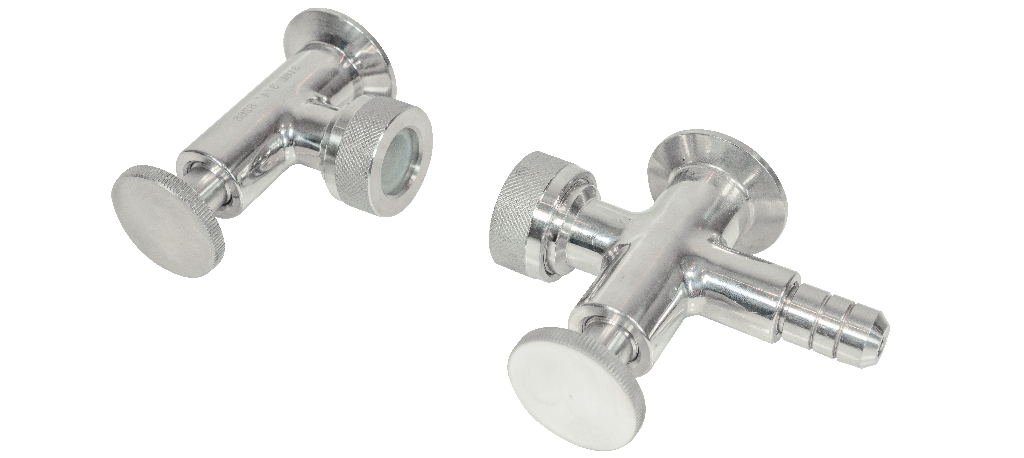

The Liquid Level Gauge is made up of two parts, known as the ‘Upper’ and ‘Lower’ fitting. These are used with 19.05mm polycarbonate or borosilicate glass tube.

This tube is friction fitted between the two fittings into a silicone seal at the outlets. This allows fluid to flow up to a maximum temperature of 180°C. Each unit has a stainless steel retaining nut. The nut acts as handwheel to gauge the flow through the tube and a 25.4-38.1m Tri Clover connection to let the liquid enter and exit.

As the name suggests, liquid levels of tanks or barrels can be gauged by positioning the Upper Gauge at the top of the tank and the Lower Gauge near the bottom. This allows an external view of the liquid level within.

The individual gauges are able to withstand a maximum pressure of 145PSI (10Bar); however, this may be less depending on the glass tube handling pressure.